In Oak Harbor, Ohio, micro etching—a cutting-edge manufacturing process using chemical or plasma removal—creates intricate microscopic patterns crucial for industries like electronics and medical devices. This technique enables the production of smaller, faster components with enhanced performance, pushing technological boundaries. Advanced micro etching techniques offer unparalleled control, allowing features as small as 1 micrometer, benefiting semiconductors, medical devices, and artistic applications. Located in a hub for advanced manufacturing, Oak Harbor showcases how micro etching drives innovation, enhances product performance, and enables complex designs. Despite challenges, continuous innovations like AI integration are poised to revolutionize micro etching, solidifying its importance in modern manufacturing across diverse sectors.

“Unveiling the Precision of Advanced Micro Etching Techniques: A Comprehensive Guide. This article explores the intricate world of micro etching, a revolutionary process shaping diverse industries. From its foundational understanding to modern advancements, we delve into how micro etching in Oak Harbor, Ohio, is pushing boundaries. Discover the multifaceted benefits, from enhanced product quality to innovative applications across sectors. We present a case study, offering insights into real-world transformations. Moreover, this guide anticipates future trends, highlighting the potential of micro etching to unlock unprecedented possibilities.”

- Understanding Micro Etching: A Brief Overview

- Advanced Micro Etching Techniques: The Modern Approach

- Benefits of Micro Etching in Various Industries

- The Role of Micro Etching Process Oak Harbor Ohio: A Case Study

- Challenges and Future Prospects of Micro Etching

- Conclusion: Unlocking the Potential with Micro Etching

Understanding Micro Etching: A Brief Overview

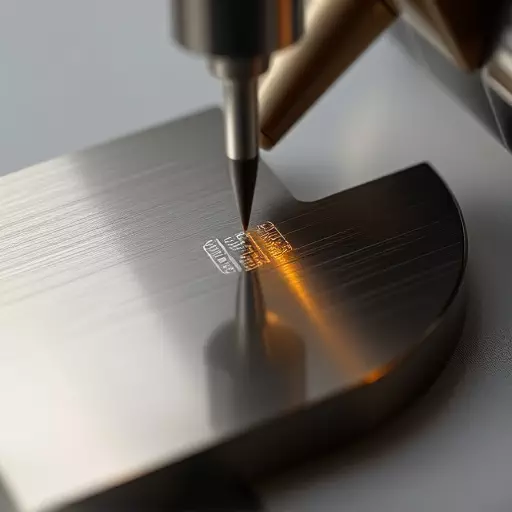

Micro etching is a highly precise and advanced manufacturing technique that involves the controlled removal of material from a substrate using etched chemicals or plasma. This process enables the creation of intricate patterns, structures, and features at a microscopic level, often in the range of micrometers (microns). By employing specialized equipment and extreme precision, micro etching opens doors to numerous applications across various industries, including electronics, semiconductor manufacturing, and medical devices.

In Oak Harbor, Ohio, the benefits of micro etching are widely recognized and utilized. This advanced technique allows for the production of smaller, faster, and more efficient components. Micro etching enhances product performance by enabling the integration of complex designs and structures that would be challenging or impossible to achieve with traditional manufacturing methods. Its versatility makes it an indispensable tool for engineers and manufacturers, pushing the boundaries of what’s possible in modern technology.

Advanced Micro Etching Techniques: The Modern Approach

Advanced Micro Etching Techniques represents a modern approach to precision manufacturing, offering unprecedented control and versatility in shaping materials at the microscopic level. These techniques, available in Oak Harbor, Ohio, go beyond traditional methods by employing sophisticated equipment and specialized chemicals to etch features as small as 1 micrometer or less. The benefits of micro etching are vast, ranging from improved device performance in electronics to enhanced aesthetic qualities in various industries.

In the realm of micro etching, precision is key. Modern techniques enable the creation of intricate patterns and structures with exceptional accuracy, leading to advancements in fields such as semiconductor manufacturing, medical device design, and even artistic applications. This advanced process not only enhances product functionality but also opens doors to innovative solutions that were once considered impossible, solidifying its place as a game-changer in modern production methods.

Benefits of Micro Etching in Various Industries

The benefits of micro etching are vast and far-reaching, impacting numerous industries that rely on precision and intricate detailing. This advanced micro etching process, available in Oak Harbor, Ohio, offers a multitude of advantages, from enhancing product performance to enabling innovative designs. In electronics, for instance, micro etching is crucial for creating complex circuit patterns on tiny substrates, leading to smaller, faster, and more efficient devices.

In fields like healthcare and aerospace, the benefits are equally profound. Micro etching allows for the fabrication of precise medical implants with intricate geometries, improving patient outcomes. Aerospace components benefit from enhanced durability and lighter weights achieved through micro etching techniques. Moreover, the process facilitates the creation of microscale structures in materials, opening doors to advancements in energy storage, sensors, and even personalized medicine, thus underscoring its pivotal role in shaping various sectors’ future prospects.

The Role of Micro Etching Process Oak Harbor Ohio: A Case Study

The city of Oak Harbor, Ohio, has emerged as a prominent hub for advanced manufacturing and precision engineering, with its local industries adopting cutting-edge micro etching techniques to stay ahead in their respective fields. This case study highlights the transformative power of micro etching in shaping modern production processes.

Oak Harbor’s success story is a testament to the numerous benefits of micro etching. The process allows for the creation of intricate patterns and structures on various materials, enabling manufacturers to produce components with enhanced performance and precision. From micro-electromechanical systems (MEMS) to advanced semiconductor devices, micro etching has revolutionized the way products are designed and fabricated. Local companies in Oak Harbor have leveraged this technology to create innovative solutions, ensuring their competitiveness in a global market driven by miniaturization and improved device functionality.

Challenges and Future Prospects of Micro Etching

The micro etching process faces several challenges that researchers and engineers are actively working to overcome. One significant hurdle is achieving high precision and control while scaling down to the microscopic level. The intricate nature of micro etching requires constant innovation in equipment and techniques to meet the demands of ever-smaller features and patterns. Additionally, material science plays a pivotal role; selecting suitable materials that can withstand the harsh conditions of etching while maintaining dimensional integrity is an ongoing challenge.

Looking ahead, the future of micro etching holds immense promise for various industries. Advancements in technology, such as the integration of artificial intelligence and machine learning, could lead to more automated and efficient processes. Furthermore, the development of new materials and improved etching techniques will enable the creation of more complex and intricate structures. The benefits of micro etching, including enhanced performance, miniaturization, and cost-effectiveness, are expected to drive innovation in fields like electronics, biomedicine, and energy storage, solidifying its position as a pivotal process in modern manufacturing.

Conclusion: Unlocking the Potential with Micro Etching

The intricate world of micro etching in Oak Harbor, Ohio, has unlocked a realm of possibilities for innovation and precision. This advanced technique involves the meticulous removal of material from a substrate, enabling the creation of minute structures and patterns. By employing specialized equipment and precise control, manufacturers can achieve an extraordinary level of detail that was once unattainable.

The benefits of micro etching are vast. It allows for the development of smaller, faster, and more efficient devices, pushing the boundaries of technology. From medical implants to semiconductor chips, this process ensures enhanced performance and functionality. The versatility of micro etching means it can be tailored to diverse industries, making it an indispensable tool in modern manufacturing.