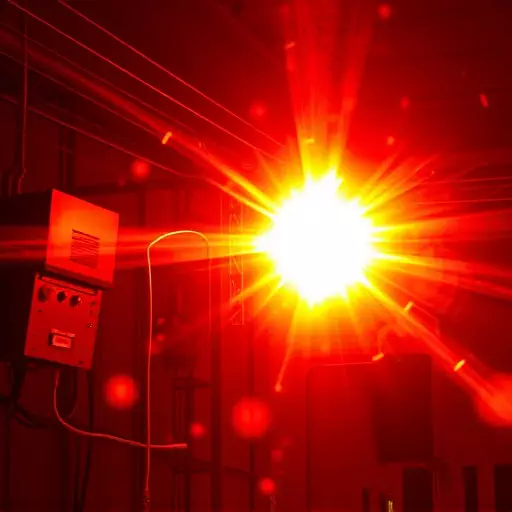

Arc flash testing is an essential process for ensuring electrical safety in industrial environments by identifying and mitigating potential hazards. It involves a comprehensive analysis of equipment design, operation, and maintenance to predict arc flash events. Through this study process, organizations can establish effective arc flash safety standards, including personal protective equipment (PPE) guidelines and de-energization procedures, significantly reducing the risk of severe burns and injuries. This begins with gathering electrical system data, simulating faults, calculating arc flash intensity using recognized models, and implementing safety programs to minimize exposure to electrical hazards, thereby creating a safer work environment for high-voltage equipment handlers.

Electrical equipment arc flash testing is a critical component of ensuring workplace safety in industrial settings. This comprehensive guide delves into the arc flash study process, emphasizing its role in identifying and mitigating electrical hazards. We explore best practices aligned with arc flash safety standards, providing insights into how to conduct thorough assessments and implement effective protective measures. By understanding the intricacies of this process, facilities can significantly reduce risks associated with electrical equipment.

Arc flash testing is a critical component in ensuring electrical safety within industrial environments. The arc flash study process involves a comprehensive evaluation of potential hazards associated with electrical systems. This includes analyzing equipment design, operation, and maintenance practices to identify any risks that could lead to an arc flash event. By conducting a thorough electrical hazard analysis, organizations can implement appropriate arc flash safety standards, such as personal protective equipment (PPE) guidelines and proper de-energization procedures, to protect workers from severe burns and other injuries.

The process begins with gathering detailed information about the electrical system, including circuit diagrams and component specifications. This data is then utilized to simulate various fault conditions and calculate the resulting arc flash intensity using recognized formulas and models. The results of this analysis guide the development of safety programs and protocols that minimize exposure to electrical hazards, ultimately fostering a safer work environment for personnel who regularly interact with high-voltage equipment.