The micro etching process in Oak Harbor, Ohio, is a versatile manufacturing technology revolutionizing industries with its ability to create intricate patterns on microscopic scales. This advanced technique offers significant benefits, from enhanced material properties and improved device performance to unique aesthetic possibilities. It finds applications in electronics, aerospace, medical devices, and art, enabling the production of high-quality, precision-engineered components and fostering innovation in nanotechnology.

“Unleash the power of precision with micro etching—a revolutionary technique transforming industries. This article explores the intricate world of micro etching in Oak Harbor, Ohio, delving into its defining process and remarkable benefits. From creating complex patterns on diverse materials to enabling advanced manufacturing and customization, micro etching is a game-changer. Discover how this technology is reshaping the landscape of craftsmanship and innovation, offering endless possibilities for designers, engineers, and creators alike.”

What is Micro Etching?

Micro etching is an advanced manufacturing process that involves creating intricate patterns on a microscopic level. It’s a highly precise technique used to shape and modify surfaces, offering immense versatility in various industries. This method is particularly prominent in Oak Harbor, Ohio, where it has revolutionized the production of specialized materials and components.

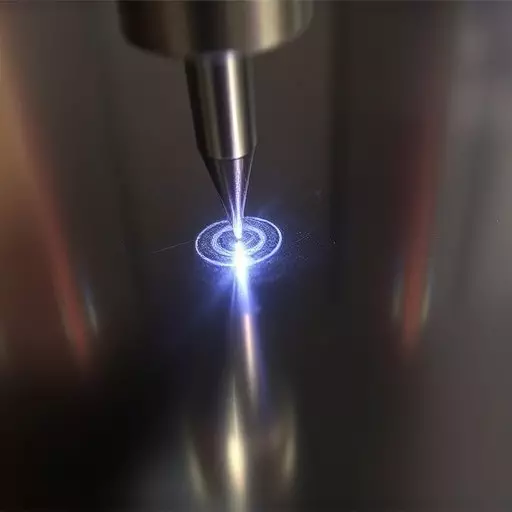

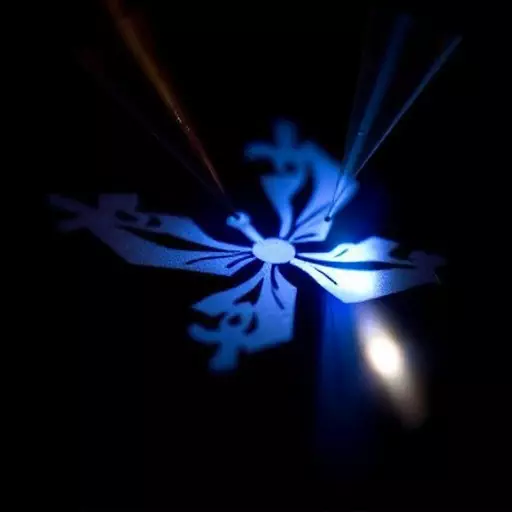

The micro etching process utilizes focused etchant solutions or ions to carve out desired patterns on substrates like silicon wafers, metal sheets, or glass. This technology offers numerous benefits, including improved material properties, enhanced device performance, and the ability to create structures as small as a few nanometers in size. It finds applications across fields such as electronics, aerospace, medical devices, and even artistic sculptures, where its precision and control are invaluable.

The Micro Etching Process in Oak Harbor, Ohio

In the heart of Oak Harbor, Ohio, a precise and intricate art form is brought to life through the Micro Etching Process. This advanced technique allows for the creation of incredibly detailed patterns on various materials, opening up a world of possibilities for designers and manufacturers. The process involves using specialized equipment to etch microscopic lines and structures onto surfaces, creating textures or artwork that can’t be achieved with traditional methods.

The benefits of micro etching are numerous. It enhances product aesthetics by adding unique, subtle patterns that capture light differently, giving products a premium look and feel. Micro etching also improves functionality, as precise etchings can create anti-reflective coatings, improve heat dissipation, or enhance the structural integrity of materials. This versatile process is applied across diverse industries, from electronics to aerospace, demonstrating its universal appeal and importance in modern manufacturing.

Benefits of Micro Etching

Micro etching offers a multitude of benefits for various industries and applications. One of its key advantages is the ability to create intricate patterns with precision on a micro-scale, which is ideal for manufacturing tiny components used in electronics, sensors, and medical devices. This highly specialized technique allows for detailed designs that are often impossible to achieve with traditional machining methods, ensuring superior product quality and performance.

In Oak Harbor, Ohio, the micro etching process has gained prominence due to its versatility and effectiveness. Local manufacturers leverage this technology to enhance their product offerings, from creating custom circuits on PCBs to producing precise structural components for advanced technologies. The benefits extend beyond industry applications; it also facilitates research and development by enabling scientists to study and manipulate materials at microscopic levels, paving the way for groundbreaking innovations in nanotechnology and material science.