Automotive foam inserts, especially custom-made ones, are vital in protecting vehicle components during shipping and handling, particularly in busy industrial areas like Holland, Ohio. These specialized insulators are designed to fit unique part dimensions, ensuring the safe delivery of delicate items like catalytic converters by absorbing shock and vibration. Custom automotive foam inserts have transformed shipping practices, offering an effective solution for both personal and commercial needs in the region.

In the world of automotive logistics, protecting delicate components during transit is paramount. Custom automotive foam inserts have emerged as a game-changer, offering unparalleled safety and security for fragile parts. This article delves into the innovative use of foam inserts specifically designed for catalytic converters, exploring their customization options and significant benefits. From enhancing protection to ensuring efficient shipping in Holland, Ohio, these inserts are a smart choice for auto manufacturers navigating the challenges of modern logistics.

- Understanding Foam Inserts: A Protective Solution for Automotive Components

- Customization and Benefits: Why Automotive Foam Inserts are a Smart Choice

- Shipping and Beyond: The Role of Foam Inserts in Safeguarding Delicate Parts in Holland, Ohio

Understanding Foam Inserts: A Protective Solution for Automotive Components

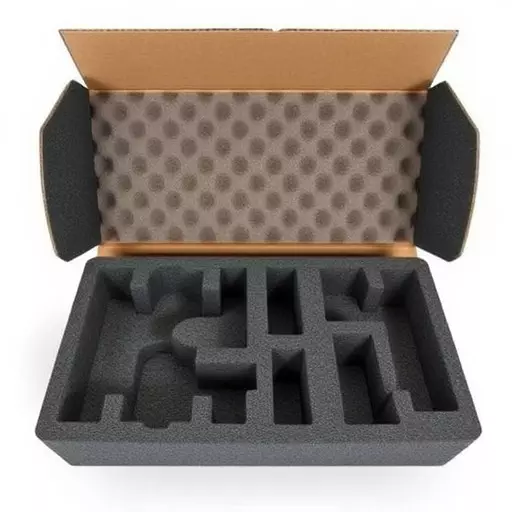

Foam inserts have emerged as a critical component in the automotive industry, offering a protective solution for various parts during shipping and handling. These inserts are meticulously designed to accommodate and safeguard fragile automotive components, ensuring they reach their destinations intact. Custom automotive foam inserts, in particular, are a game-changer for manufacturers and logistics companies. By understanding the unique dimensions and characteristics of each part, custom inserts can be crafted to provide precise protection.

In the world of automotive shipping, where components travel across vast distances, these foam inserts play a vital role. They act as a cushion, absorbing shock and vibration during transit, which is particularly crucial for delicate parts like catalytic converters. The bustling logistics landscape in Holland, Ohio, and beyond demands innovative solutions to protect fragile items, making custom foam inserts an indispensable tool for maintaining the integrity of automotive components.

Customization and Benefits: Why Automotive Foam Inserts are a Smart Choice

Shipping and Beyond: The Role of Foam Inserts in Safeguarding Delicate Parts in Holland, Ohio

In the world of automotive manufacturing and logistics, safeguarding delicate components during transit is paramount, especially in regions like Holland, Ohio, known for its bustling industry. Custom automotive foam inserts play a pivotal role in this regard, offering a protective solution for fragile parts. These specialized inserts are meticulously designed to fit various vehicle components, ensuring they remain secure and unscathed during shipping. By utilizing innovative foam materials, these custom inserts create a cushion that absorbs shocks and vibrations, preventing damage caused by rough handling.

For instance, when dealing with catalytic converters—delicate yet essential automotive parts—foam inserts become indispensable. These insulators are crafted to perfectly encase the converter’s intricate structure, providing a buffer against potential hazards. In Holland, Ohio’s manufacturing hub, where precision and efficiency reign, incorporating foam inserts into shipping practices has revolutionized the way fragile components are transported. This simple yet effective strategy ensures that automotive parts reach their destinations without a scratch, contributing to streamlined production processes and satisfied customers across the region.