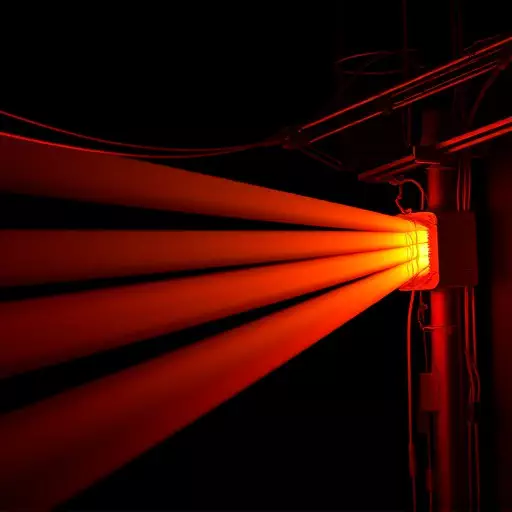

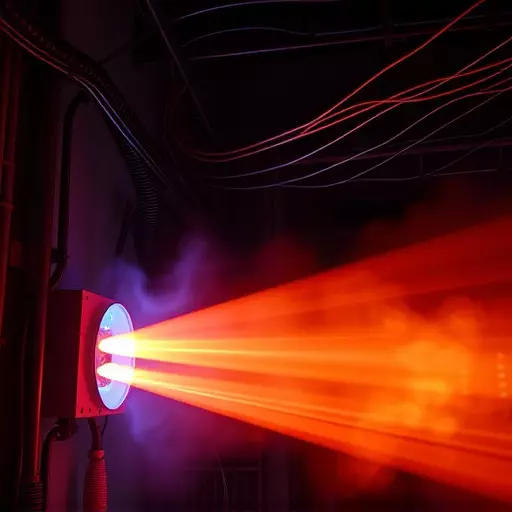

Arc flash hazards in industrial settings require structured studies involving electrical installations evaluation, arcing potential identification, and risk assessment using advanced techniques. Compliance with arc flash safety standards set by organizations like NFPA ensures regular updates to risk management, protective equipment, and training protocols, thereby enhancing workplace safety through best practices tailored to evolving technology.

Arc flash hazards pose significant risks in industrial settings, often leading to severe injuries and property damage. This article delves into the critical aspect of arc flash documentation, a comprehensive guide for facilities managers and electricians. We explore the arc flash study process, emphasizing its role in electrical hazard analysis. By understanding safety standards and implementing best practices, professionals can mitigate risks effectively. Discover how thorough documentation ensures compliance and fosters a culture of arc flash safety.

Arc flash hazards are a significant concern in industrial and commercial settings, often resulting from electrical systems and equipment. To mitigate these risks, organizations increasingly turn to a structured arc flash study process. This involves a thorough evaluation of electrical installations, identifying potential sources of arcing, and assessing their associated dangers. By employing advanced analysis techniques, professionals can pinpoint vulnerable areas and implement appropriate safety measures.

The arc flash safety standards, established by organizations like NFPA (National Fire Protection Association), provide guidelines for risk assessment, protective equipment requirements, and training protocols. Adhering to these standards ensures a comprehensive approach to managing electrical hazards. Regular updates and revisions in these guidelines reflect the evolving nature of technology and best practices in arc flash protection, ensuring a safer working environment for employees.