Arc Flash Hazard Analysis (AFHA) is a comprehensive process to identify and mitigate risks associated with electrical systems, aiming to prevent severe injuries or fatalities. By evaluating equipment design, energy levels, and maintenance records, professionals implement targeted strategies for arc flash risk reduction. This includes improved system design, enhanced personal protective equipment (PPE), and rigorous maintenance protocols. Advanced technologies like smart sensors, machine learning, and real-time monitoring revolutionize AFHA, enabling data-driven solutions tailored to specific workplace risks. Case studies demonstrate significant risk reductions in diverse industries, showcasing the value of arc flash prevention technologies for electrical safety compliance and asset protection. Future trends include leveraging data analytics, predictive modeling, IoT, AI, VR, and AR for more precise analyses, proactive safety measures, and enhanced worker training, ultimately enhancing electrical safety compliance and arc flash risk reduction.

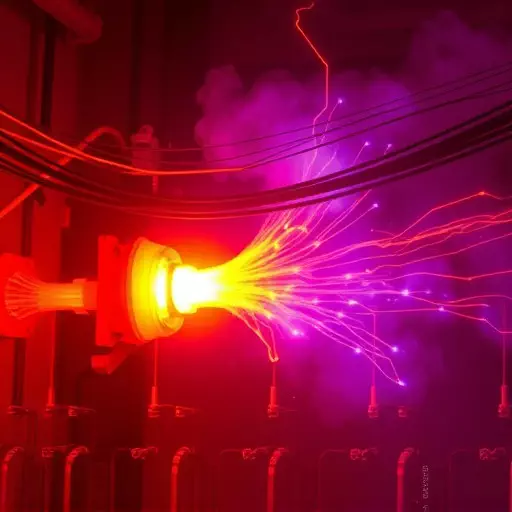

In today’s industrial landscape, understanding and mitigating arc flash hazards is paramount for workplace safety. This comprehensive guide explores the latest trends in arc flash prevention technology, focusing on key aspects such as hazard analysis, risk reduction strategies, advanced detection devices, regulatory compliance, innovative solutions, and future advancements. By delving into these areas, we aim to equip professionals with insights crucial for implementing effective electrical safety measures, adhering to industry standards, and minimizing arc flash risks in industrial environments.

- Understanding Arc Flash Hazard Analysis: Identifying Risks in Electrical Systems

- The Importance of Arc Flash Risk Reduction Strategies for Workplace Safety

- Advanced Technology in Arc Flash Detection and Protection Devices

- Electrical Safety Compliance: Regulations and Standards for Arc Flash Mitigation

- Innovative Solutions for Arc Flash Prevention in Industrial Environments

- Case Studies: Successful Implementation of Arc Flash Prevention Technologies

- Future Trends and Advancements in Arc Flash Management

Understanding Arc Flash Hazard Analysis: Identifying Risks in Electrical Systems

Arc Flash Hazard Analysis plays a pivotal role in identifying and mitigating risks associated with electrical systems. It involves a comprehensive assessment to understand the potential for arc flash events, which can cause severe injuries or even fatalities. By analyzing factors like equipment design, energy levels, and maintenance records, professionals can pinpoint areas of vulnerability. This process is crucial in the context of electrical safety compliance, as it enables the implementation of targeted strategies to reduce arc flash risk.

Identifying risks early on allows for proactive measures to be taken, such as improving system design, enhancing personal protective equipment (PPE), and establishing rigorous maintenance protocols. Regular audits and updates to these analyses are essential to adapt to changes in electrical systems, ensuring ongoing electrical safety compliance.

The Importance of Arc Flash Risk Reduction Strategies for Workplace Safety

Advanced Technology in Arc Flash Detection and Protection Devices

Electrical Safety Compliance: Regulations and Standards for Arc Flash Mitigation

Innovative Solutions for Arc Flash Prevention in Industrial Environments

In recent years, innovative solutions have emerged to address the critical issue of arc flash prevention in industrial environments. These advanced technologies are revolutionizing electrical safety compliance by offering more precise and effective strategies for mitigating the arc flash hazard analysis. Traditional methods often relied on general risk reduction measures, but modern approaches focus on customized, data-driven solutions tailored to specific workplace risks.

By leveraging smart sensors, machine learning algorithms, and real-time monitoring systems, facilities can now conduct in-depth arc flash risk assessments. This enables targeted interventions, such as improved equipment design, enhanced protective gear, and intelligent circuit protection devices. These innovative solutions not only reduce the likelihood of arc flash incidents but also streamline regulatory compliance, ensuring a safer working environment for industrial personnel.

Case Studies: Successful Implementation of Arc Flash Prevention Technologies

Case studies demonstrate the successful implementation of arc flash prevention technologies across various industries, highlighting their effectiveness in mitigating risks and enhancing electrical safety compliance. These real-world examples illustrate how arc flash hazard analyses have led to significant reductions in potential dangers. By identifying high-risk areas and equipment, companies have been able to implement targeted strategies, such as improved engineering controls, personal protective equipment (PPE), and training programs.

For instance, a study in a chemical processing plant revealed that by conducting thorough arc flash risk assessments and installing advanced suppression systems, the facility achieved a 75% decrease in potential arc flash incidents. Similarly, a manufacturing plant’s proactive approach to electrical safety, including regular maintenance and the use of innovative insulation materials, resulted in zero reported arc flash events over a five-year period. These success stories underscore the value of investing in arc flash prevention technologies, ultimately saving lives and assets.

Future Trends and Advancements in Arc Flash Management

As technology continues to evolve, so do the methods for managing and mitigating arc flash hazards. Future trends in arc flash prevention are expected to focus on enhanced data analytics and predictive modeling, enabling more accurate risk assessments and proactive safety measures. The integration of Internet of Things (IoT) devices and advanced sensors will facilitate real-time monitoring of electrical systems, allowing for immediate detection of anomalies that could lead to arc flashes.

Artificial intelligence (AI) and machine learning algorithms will play a pivotal role in analyzing vast data sets from arc flash hazard analyses, identifying patterns, and predicting potential risks. These advancements will not only improve electrical safety compliance but also optimize maintenance schedules, reducing downtime and operational costs. Furthermore, virtual reality (VR) and augmented reality (AR) technologies are poised to revolutionize training programs, providing immersive experiences that prepare workers for real-world arc flash scenarios, thereby enhancing overall workplace safety.