CNC machining in Holland, Ohio, has revolutionized electronics packaging with advanced, custom protective foam inserts. These foams offer superior shock absorption and vibration dampening, ensuring device safety during transport. Furthermore, they incorporate ESD (Electrostatic Discharge) safety features, crucial for industries handling delicate electronics. CNC technology allows precise production of these specialized anti-static foam inserts, setting new industry standards and promoting sustainable packaging practices while safeguarding sensitive components from damage and static electricity hazards.

“Discover how CNC machining is transforming packaging, especially in Holland, Ohio. From revolutionizing protection with specialized electronic packaging to crafting custom foam inserts tailored to unique device shapes, this technology offers unparalleled precision and efficiency. Learn about ESD-safe anti-static foam, vital for sensitive electronics, and explore the cost-effective, sustainable benefits of CNC machining for packaging industries, including the creation of protective foam inserts for electronics in Holland, Ohio.”

- Revolutionizing Protection: CNC Machining for Electronics Packaging in Holland, Ohio

- Customization at its Finest: Creating Unique Foam Inserts for Specific Electronics

- ESD-Safe Solutions: Why Anti-Static Foam is Essential for Sensitive Electronics

- The Role of CNC Machining in Achieving Precision and Efficiency in Insert Design

- Sustainability and Cost-Effectiveness: Benefits of CNC Machining for Packaging Industries

Revolutionizing Protection: CNC Machining for Electronics Packaging in Holland, Ohio

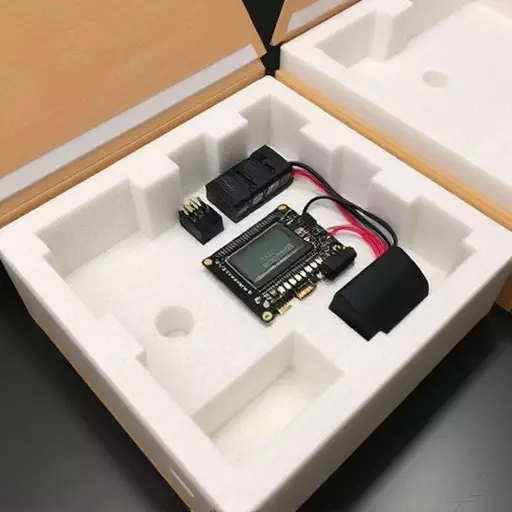

In Holland, Ohio, CNC machining has revolutionized the way electronics are packaged, offering unprecedented levels of protection for sensitive components. The precise and customizable nature of Computer Numerical Control (CNC) technology allows for the creation of advanced protective foam inserts tailored to specific electronic devices. These custom foam inserts go beyond standard packaging by ensuring optimal shock absorption and vibration dampening during transportation, reducing the risk of damage to valuable electronics.

Moreover, CNC machining enables the production of ESD-safe (Electrostatic Discharge) foam inserts, a crucial consideration for industries where static electricity can cause severe harm to delicate electronic parts. These specialized anti-static foam materials create a safe, controlled environment, minimizing the impact of electrostatic discharge and maintaining the integrity of sensitive components. With these innovations, Holland, Ohio, stands as a prime example of how CNC machining is transforming electronics packaging, enhancing protection, and setting new standards in the industry.

Customization at its Finest: Creating Unique Foam Inserts for Specific Electronics

In the realm of packaging solutions, CNC machining has revolutionized the way electronic components are protected during transit and storage. One of its standout applications is the creation of custom foam inserts tailored to specific electronics in Holland, Ohio. This precision-based manufacturing process enables the production of intricate and unique foam shapes that perfectly cradle sensitive devices, ensuring their safe arrival at destinations. By leveraging CNC machining, manufacturers can transform the packaging experience for electronic goods.

Custom foam inserts go beyond standard protection by offering specialized features such as ESD (Electrostatic Discharge) safety through antistatic foams, which are particularly crucial for high-tech electronics. These custom designs not only protect devices from physical impacts but also mitigate the risks associated with static electricity buildup—a common concern in the electronics industry. With CNC machining, achieving these precise and specialized protective foam inserts is efficient, cost-effective, and a game-changer when it comes to maintaining product integrity.

ESD-Safe Solutions: Why Anti-Static Foam is Essential for Sensitive Electronics

In the realm of packaging, especially for sensitive electronic components, ESD (Electrostatic Discharge) safety is paramount. One effective solution that has gained prominence is the use of anti-static foam inserts, a crucial component in ensuring product integrity during transportation and storage. These specialized protective foam inserts for electronics Holland Ohio are not just standard packing materials; they act as a barrier against the damaging effects of ESD events. By incorporating custom foam inserts designed with ESD-safe properties, manufacturers can safeguard their delicate electronics from unexpected voltage spikes that can cause irreversible damage.

The necessity for ESD-safe solutions is underscored by the increasing prevalence of miniaturized and high-density electronic devices. Anti-static foam, meticulously crafted to fit specific product dimensions, provides a secure nesting place for these components, reducing movement and friction that could trigger electrostatic discharge. This proactive approach to packaging not only minimizes the risk of product failure but also ensures the longevity and functionality of sensitive electronics, making custom foam inserts an indispensable asset in modern manufacturing practices.

The Role of CNC Machining in Achieving Precision and Efficiency in Insert Design

CNC machining plays a pivotal role in achieving precision and efficiency when designing protective foam inserts for electronics, such as those needed by companies providing services in Holland, Ohio. This advanced manufacturing process allows for the creation of intricate custom foam inserts that safeguard delicate electronic components during transportation and storage. By leveraging CNC technology, manufacturers can produce ESD-safe (Electrostatic Discharge) foam inserts that prevent damaging static buildup, a critical consideration for maintaining the integrity of sensitive electronics.

The precision afforded by CNC machining ensures that anti-static foam for electronics is tailored to fit specific product dimensions perfectly. This not only prevents damage but also optimizes space utilization within packaging. Moreover, the efficiency of CNC machining translates into faster production times and reduced costs, making it a preferred choice for companies seeking high-quality, specialized protective foam inserts.

Sustainability and Cost-Effectiveness: Benefits of CNC Machining for Packaging Industries

In today’s competitive market, packaging plays a crucial role in protecting products while reducing waste and environmental impact. CNC machining offers significant advantages in this regard, making it an attractive option for the packaging industry. One notable benefit is its contribution to sustainability. Through precise cutting and shaping of materials like foam, CNC machinery enables the creation of custom protective foam inserts tailored to specific product needs. This reduces over-packaging and minimizes waste, aligning with growing consumer demands for eco-friendly practices.

Moreover, CNC machining enhances cost-effectiveness. Automated processes streamline production, lowering labor costs and minimizing errors. Custom foam inserts, including ESD-safe and anti-static varieties essential for protecting electronics in Holland, Ohio, can be produced efficiently. This precision ensures that products arrive at their destination in optimal condition, reducing damage and returns, thereby saving businesses money in the long run.