Pavement milling and grinding are critical processes for maintaining highway safety and longevity, and Toledo, Ohio, exemplifies their effective application. Specialized crews in the city use advanced equipment to meticulously remove road surfaces, preparing them for repairs and resurfacing, even amidst heavy traffic and diverse weather conditions. This precision work ensures a smooth base for new asphalt layers, reflecting Toledo's dedication to sustainable highway maintenance. The process not only addresses immediate repair needs but also significantly extends the life and safety of roadways, facilitating efficient traffic flow and conserving materials through recycling. Pavement milling and grinding in Toledo showcases a model approach for urban infrastructure renewal, demonstrating its importance in Ohio's transportation network by providing a smoother, more durable road surface that benefits drivers statewide. The operational excellence of Toledo's pavement milling and grinding operations underscores the efficiency and sustainability of this practice, making it a key component for public infrastructure upkeep across the region.

Road maintenance is a critical aspect of ensuring public safety and infrastructure longevity. This article delves into the essential role of pavement milling and grinding in highway repair, with a particular focus on Toledo, Ohio. We explore the intricacies of this process, its environmental and economic benefits, and how it contributes to the upkeep of roadways. Through a case study of Toledo’s operations, readers will gain insights into the practical applications and advantages of pavement milling and grinding as a key component in effective road maintenance strategies.

- Overview of Pavement Milling and Grinding in Highway Repair

- The Process of Pavement Milling and Grinding in Toledo, Ohio

- Benefits of Implementing Pavement Milling and Grinding for Road Maintenance

- Case Study: Pavement Milling and Grinding Operations in Toledo, Ohio

Overview of Pavement Milling and Grinding in Highway Repair

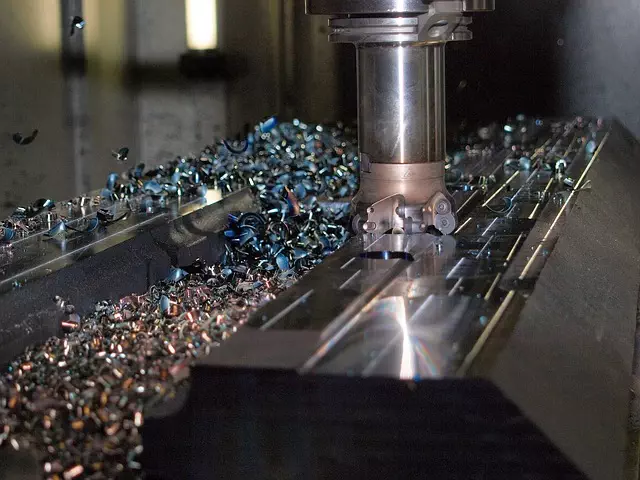

Pavement milling and grinding play a critical role in the maintenance and repair of highways, ensuring road safety and longevity. This process involves the removal of the surface course or layer of asphalt from a road to prepare it for repairs, resurfacing, or reconstruction. In highway repair, pavement milling and grinding serve as the first step in the rehabilitation process. The equipment used for this purpose, such as milling machines and grinding machines, precisely cuts and levels the remaining surface to create a smooth, even base for new asphalt layers. This meticulous process ensures that the subsequent layers of asphalt adhere properly and extend the lifespan of the road. In Toledo, Ohio, this operation is conducted by specialized crews who navigate the unique challenges posed by the region’s heavy traffic volumes and diverse weather conditions. The skillful execution of pavement milling and grinding in Toledo is a testament to the city’s commitment to maintaining its highway infrastructure safely and efficiently. The process not only facilitates immediate repairs but also contributes to the overall condition of the road network, enhancing driver safety and improving traffic flow.

The Process of Pavement Milling and Grinding in Toledo, Ohio

Benefits of Implementing Pavement Milling and Grinding for Road Maintenance

Pavement milling and grinding play a critical role in maintaining the integrity and safety of highways and roadways. This process involves the removal of the top layer of asphalt or concrete from a paved surface using specialized machinery. The benefits of implementing pavement milling and grinding for road maintenance are manifold. Firstly, it allows for the precise removal of deteriorated or damaged surfaces without the need to replace the entire pavement structure. This targeted approach minimizes material waste and reduces costs associated with full-depth repairs. Furthermore, the process prepares the surface for new asphalt or concrete to be laid, ensuring a smooth and durable finish that can extend the lifespan of the road by several years. The accuracy of milling operations also means that any markings or line paintings on the road are preserved, which is essential for maintaining traffic flow and safety. In fact, the precision of milling equipment ensures that the subbase and base layers are undisturbed, preserving the structural strength of the road. For instance, in Toledo Ohio, municipalities and contractors have utilized pavement milling and grinding to efficiently maintain roads, demonstrating its effectiveness in various climates and traffic conditions. This not only enhances the driving experience but also contributes to the longevity and safety of our transportation infrastructure. The use of advanced milling machines equipped with laser guidance systems further enhances the precision and efficiency of this process, making it an indispensable tool for modern road maintenance practices.

Case Study: Pavement Milling and Grinding Operations in Toledo, Ohio

In Toledo, Ohio, the process of pavement milling and grinding has proven to be an indispensable aspect of highway repair and maintenance. This meticulous operation involves the precise removal of the surface course of asphalt pavements, enabling infrastructure crews to address underlying issues such as damage or base layer reconstruction. The city’s use of specialized milling machines ensures that the depth of material removed is consistent and accurate, which is vital for the subsequent repair work. This process not only extends the lifespan of the road but also provides a smooth and durable surface once resurfacing is complete. The efficiency and precision of pavement milling and grinding in Toledo are exemplified by its application on major thoroughfares, where minimal disruption to traffic flow is paramount. The recycled material from the milling process is often reused in new pavements, underscoring the city’s commitment to sustainability and resource management within its infrastructure projects.

The impact of pavement milling and grinding operations in Toledo extends beyond mere repair; it encompasses the enhancement of road safety, traffic flow, and overall driving experience. The high-quality results achieved through this process contribute to a more reliable transportation network, which is essential for both local commuters and interstate travelers. The city’s investment in state-of-the-art milling equipment and trained personnel ensures that these operations are carried out with the utmost proficiency, setting a standard for urban infrastructure maintenance across Ohio and beyond.