The article details the complexities and benefits of pavement milling and grinding in Toledo, Ohio, a vital process for road reconstruction and maintenance. It addresses the unique challenges posed by Toledo's geographic location, traffic density, environmental concerns, and variable weather, emphasizing the importance of coordinating with traffic control measures to minimize disruptions. The operations are environmentally sensitive due to Toledo's proximity to water bodies, necessitating strict adherence to regulations to manage potential contaminants. The integration of historical infrastructure with modern techniques adds complexity, requiring contractors and municipal teams to navigate both mechanical and logistical challenges while ensuring safety for all parties involved. Advanced technology, strategic planning, and intimate knowledge of Toledo's infrastructure needs are essential for the success of these operations, which provide socio-economic advantages, including maintaining a robust transportation network that supports commerce and enhances public safety. The city has adopted best practices to mitigate environmental challenges such as dust and noise emissions during pavement milling and grinding, with strategies like water sprays, advanced filtration systems, and scheduling operations at less disruptive times. These sustainable practices demonstrate Toledo's commitment to environmental stewardship and sustainable urban development while highlighting the economic benefits of using pavement milling and grinding as a sustainable infrastructure practice in Ohio. The article concludes by noting the cost-effectiveness of this method, its long-term economic benefits for cities like Toledo, and the potential for other urban areas to learn from Toledo's experience in optimizing these processes through technological advancements.

Pavement milling and grinding are indispensable processes in modern infrastructure maintenance, particularly as urban landscapes evolve. Toledo, Ohio, serves as a case study for the multifaceted challenges inherent in these operations. This article delves into the intricacies of pavement milling and grinding, highlighting Toledo’s unique experiences and approaches to overcoming environmental, technological, economic, and logistical hurdles. From managing dust and noise pollution to leveraging cutting-edge machinery for enhanced efficiency and safety, the insights offered here underscore the complex nature of maintaining robust roadways in an urban setting. Join us as we explore the practical solutions and best practices that arise from Toledo’s pavement milling and grinding endeavors.

- Navigating the Complexities of Pavement Milling and Grinding Operations: A Toledo, Ohio Perspective

- Environmental Considerations in Pavement Milling and Grinding: Managing Dust and Noise in Toledo's Urban Landscape

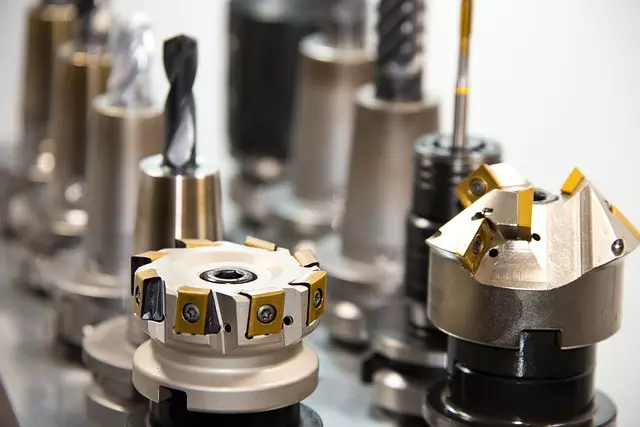

- Technological Advancements in Pavement Milling and Grinding Machinery: Enhancing Efficiency and Safety on Toledo Roadways

- Economic and Logistical Challenges in Pavement Milling and Grinding Projects: Case Studies from Toledo's Infrastructure Overhaul

Navigating the Complexities of Pavement Milling and Grinding Operations: A Toledo, Ohio Perspective

Pavement milling and grinding operations in Toledo, Ohio, present a unique set of challenges that intertwine local infrastructure needs with the broader context of urban development and maintenance. These operations are critical for road reconstruction, surface rehabilitation, and maintenance work, necessitating precise machinery and skilled operators to remove asphalt or concrete layers efficiently and prepare the substrate for new pavement applications. In Toledo, the complexities are amplified by factors such as the city’s geographic location, traffic density, environmental considerations, and seasonal weather patterns. The process of milling and grinding must be carefully synchronized with traffic control measures to minimize disruptions on already congested roadways. Additionally, the handling and disposal of the milled material must adhere to environmental regulations, as Toledo’s proximity to bodies of water necessitates a responsible approach to manage potential contaminants.

The nuances of pavement milling and grinding in Toledo are further complicated by the city’s historical infrastructure and the need to integrate modern techniques with legacy systems. The operational challenges range from the mechanical aspects, such as maintaining the machinery under diverse weather conditions, to the logistical coordination required for material transport and disposal. Contractors and municipal crews must navigate these complexities while ensuring safety for both workers and motorists. The success of these operations hinges on a combination of advanced technology, strategic planning, and a deep understanding of Toledo’s infrastructure requirements. The outcomes are not just limited to the physical resurfacing but also include the socio-economic benefits of maintaining a well-connected transportation network that supports commerce, enhances public safety, and promotes the overall quality of life in the region.

Environmental Considerations in Pavement Milling and Grinding: Managing Dust and Noise in Toledo's Urban Landscape

Pavement milling and grinding operations in Toledo, Ohio, are integral to road maintenance and reconstruction but come with their unique environmental challenges. These processes generate dust and noise, which can have significant impacts on both the urban environment and the well-being of residents. To mitigate the environmental impact of pavement milling and grinding, local authorities and contractors in Toledo implement a range of best practices. These include using water sprays to suppress dust particles that arise during the milling process, thereby reducing airborne contaminants and preventing them from dispersing into the surrounding area. Advanced machinery with efficient filtration systems is employed to minimize dust generation. Additionally, noise reduction measures are taken by scheduling operations at times that cause less disturbance to local communities, such as during off-peak hours or using quieter equipment technology where available. These efforts aim to balance the necessity of infrastructure maintenance with the need to preserve the quality of life for Toledo’s residents and protect its urban environment. The use of these technologies and scheduling strategies demonstrates a commitment to environmental stewardship and responsible urban development within the city’s landscape.

Technological Advancements in Pavement Milling and Grinding Machinery: Enhancing Efficiency and Safety on Toledo Roadways

Economic and Logistical Challenges in Pavement Milling and Grinding Projects: Case Studies from Toledo's Infrastructure Overhaul

Pavement milling and grinding are integral processes in road maintenance and infrastructure development, offering a cost-effective solution for road rehabilitation by recycling existing pavement materials. However, these projects come with their own set of economic and logistical challenges that can impact both the timeline and budget of an infrastructure overhaul. In Toledo, Ohio, these challenges have been particularly evident during recent pavement milling and grinding initiatives. The city’s aging infrastructure requires significant investment to maintain and upgrade its roadways, posing a substantial financial burden. The cost considerations extend beyond the immediate expenses of equipment rental, material costs, and labor; they also encompass the long-term savings associated with the durability and performance improvements of the recycled pavement.

Logistically, these projects demand meticulous planning and coordination. Toledo’s geographical location and traffic patterns add complexity to the process. The weather conditions in Ohio, particularly harsh winters and hot summers, can delay or expedite project timelines due to their impact on ground conditions. Additionally, the integration of milled material into new pavement layers must be managed carefully to ensure the integrity of the road structure. Case studies from Toledo’s infrastructure overhaul illustrate the importance of adaptive planning and the utilization of advanced technology to optimize these processes. For instance, the use of GPS-guided milling machines has significantly improved precision and efficiency, reducing both material waste and the time required for project completion. These advancements not only contribute to economic savings but also enhance the overall quality of Toledo’s road network. The lessons learned from Toledo’s endeavors in pavement milling and grinding provide valuable insights into navigating similar challenges across other urban infrastructure projects.