Pavement milling and grinding in Toledo, Ohio, represents a significant advancement in road maintenance, offering a sustainable and efficient approach to infrastructure upkeep. This process selectively removes compromised surface layers using specialized machinery, such as milling machines with diamond-segmented teeth, which extends the life of the road and enhances safety without complete removal. It addresses common issues like potholes and ruts, ensuring smoother roads and better ride quality by leveling surfaces. The method is not only eco-friendly, as it recycles excavated material back into new asphalt, but also cost-effective, minimizing waste and shortening road closure durations. Toledo's adoption of this technique exemplifies its commitment to integrating modern solutions that improve adhesion for new asphalt layers, enhance overall pavement performance, and contribute significantly to the longevity and safety of urban transportation systems. This method is a testament to Toledo's pioneering role in sustainable road maintenance practices, setting a practical example for cities across the nation. It underscores the importance of adopting modern, efficient methods like pavement milling and grinding to ensure high standards of road safety while extending the life of infrastructure.

When roads show signs of wear, cities and municipalities turn to pavement milling and grinding as a cost-effective and efficient solution for maintenance and renovation. This article delves into the intricacies of this process, its applications, and how it stands against other resurfacing methods. Exploring the latest advancements in pavement milling and grinding techniques, particularly as seen in Toledo, Ohio, offers a unique perspective on local road maintenance practices. We will examine the benefits, evaluate its performance against alternative options, and project future developments in this field. Join us as we traverse the landscape of roadway rejuvenation through the lens of pavement milling and grinding.

- Pavement Milling and Grinding: An Overview of the Process and Its Benefits

- Case Study: Pavement Milling and Grinding in Toledo, Ohio – A Closer Look at Local Road Maintenance

- Evaluating Pavement Milling and Grinding vs. Other Resurfacing Options

- The Future of Pavement Maintenance: Innovations in Milling and Grinding Techniques

Pavement Milling and Grinding: An Overview of the Process and Its Benefits

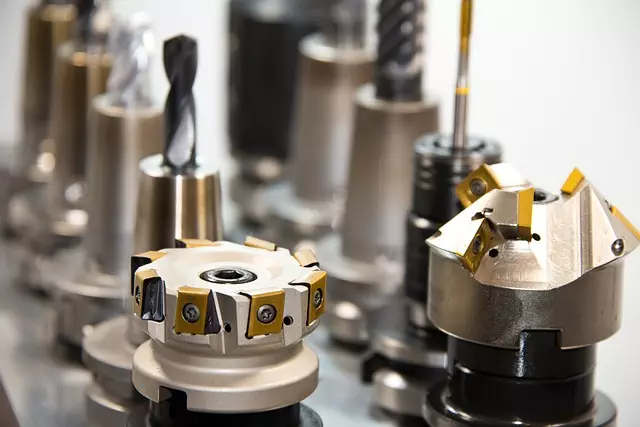

Pavement milling and grinding are integral processes in the maintenance and improvement of roadways. These techniques involve the removal of the surface layer or specific portions of a paved area to repair or resurface it, which is crucial for ensuring safe travel conditions. The process begins with the deployment of specialized machinery known as milling machines or cold grinders that are equipped with rotating drums or discs with diamond-segmented teeth. These tools precisely cut and remove the designated depth of the pavement, allowing for the extraction of damaged asphalt or concrete without the need for complete pavement removal. This selective milling can address issues like potholes, ruts, or surface irregularities.

In Toledo, Ohio, as in many cities, maintaining the integrity of the infrastructure includes the strategic use of pavement milling and grinding. The benefits of this process are manifold: it extends the life of the road, improves ride quality by leveling and smoothing the surface, and provides a clean, fresh layer that can be overlaid with new asphalt or sealant if desired. Moreover, because this method minimizes material waste and reduces the time required for road closures, it is an efficient and cost-effective solution for urban transport systems. The precision of pavement milling and grinding ensures a consistent depth removal, which facilitates better adhesion for new asphalt layers and enhances overall pavement performance. This makes it a preferred option among city planners and contractors tasked with maintaining the vast network of roads in Toledo, Ohio, contributing to the longevity and safety of the urban transportation infrastructure.

Case Study: Pavement Milling and Grinding in Toledo, Ohio – A Closer Look at Local Road Maintenance

The city of Toledo, Ohio, has implemented a strategic approach to maintaining its road infrastructure by utilizing pavement milling and grinding as part of its resurfacing efforts. This process involves removing the top layer of an existing roadway through a series of controlled operations that both grind down the surface and collect the resulting material for recycling into new pavement. The benefits of this method are manifold; it provides a smoother, more uniform surface compared to patching work done by traditional methods. Moreover, pavement milling and grinding in Toledo has proven to be cost-effective and environmentally friendly, as it reduces the need for new materials and minimizes construction waste.

The project’s success is not only measured by the quality of the road surface but also by its minimal impact on traffic flow and urban life. Toledo’s application of pavement milling and grinding has demonstrated the technique’s effectiveness in dense, metropolitan environments where maintaining traffic patterns is critical. The precision and efficiency of this method have allowed Toledo to address infrastructure issues while ensuring that the city continues to operate smoothly for residents and commuters alike. This local road maintenance initiative serves as a practical example of how pavement milling and grinding can be successfully integrated into urban infrastructure projects, showcasing Toledo’s commitment to sustainable and effective road maintenance solutions.

Evaluating Pavement Milling and Grinding vs. Other Resurfacing Options

When considering pavement resurfacing options, pavement milling and grinding emerges as a highly efficient method for maintaining road infrastructure. This process involves removing the top layer of an existing roadway to prepare for a new surface course. Pavement milling and grinding in Toledo, Ohio, or any region, offers several advantages over traditional resurfacing techniques. For one, it ensures a smoother finish with high-quality results, as the machine precisely controls depth and width, ensuring uniform removal of the pavement surface. This precision leads to a more consistent surface for the new layer to be applied, which can significantly enhance safety and extend the lifespan of the road. Additionally, the millings generated from this process can often be recycled directly into the new asphalt mix, reducing waste and promoting sustainability.

Comparing pavement milling and grinding to other resurfacing options like full-depth reclamation or overlay methods, it becomes apparent that the benefits are multifaceted. While overlay involves simply laying a new layer of asphalt on top of the existing one without removing the old surface, pavement milling offers a more thorough treatment. It can address issues such as water drainage and structural weaknesses within the road’s substructure. In Toledo, Ohio, where weather conditions necessitate robust infrastructure to handle seasonal changes, the durability and performance advantages of pavement milling and grinding make it a preferred choice for many municipalities and contractors. The technique not only refreshes the pavement visually but also reinforces its structural integrity for years to come.

The Future of Pavement Maintenance: Innovations in Milling and Grinding Techniques

In recent years, advancements in pavement milling and grinding have significantly impacted infrastructure maintenance and longevity. These techniques are critical for refurbishing road surfaces, ensuring safety and efficiency on our transportation networks. Traditionally, pavement milling and grinding in Toledo, Ohio, and similar locales involved the removal of surface layers to repair or resurface roads. Modern innovations have enhanced these processes, incorporating cutting-edge technologies that improve precision, reduce noise pollution, and minimize environmental impact. For instance, the integration of GPS guidance systems allows for more accurate milling operations, ensuring only the damaged material is removed without compromising the underlying structure. Additionally, the development of specialized grinding tools has led to finer textures on pavement surfaces, which not only improves traction but also contributes to better road performance and durability. These advancements are not only beneficial for Toledo, Ohio, but have broader implications for pavement maintenance across the United States. As a result, transportation agencies are increasingly adopting these improved milling and grinding methods to extend the life of their infrastructure while maintaining high safety standards. The future of pavement maintenance is characterized by these innovations that promise more sustainable, cost-effective, and efficient roadways for the motoring public.