CNC machining has transformed energy-efficient packaging in Holland, Ohio, by creating custom protective foam inserts for delicate electronic components. ESD-safe foam, tailored to static-sensitive parts, ensures product integrity through safe electrical charge dissipation, reducing damage and waste. Local manufacturers offer innovative designs catering to diverse product sizes, contributing to environmental sustainability and extended component lifespans. Custom foam inserts safeguard electronics from shocks, vibrations, and temperature fluctuations, making Holland a leader in ESD-safe packaging practices for advanced electronics.

“Discover how CNC machining is revolutionizing energy-efficient packaging, especially in the electronics industry. This article explores the innovative use of this technology to create precise and sustainable solutions. From understanding the fundamentals of CNC machining to delving into its local applications in Holland, Ohio, we uncover the benefits and unique requirements for protective foam inserts. Learn about custom foam designs tailored to specific needs, including ESD-safe and anti-static foams, ensuring the secure transportation of sensitive electronics.”

- Understanding CNC Machining for Energy-Efficient Packaging

- The Role of Protective Foam Inserts in Electronics Packaging

- Custom Foam Inserts: Tailoring Solutions for Specific Needs

- ESD-Safe and Anti-Static Foams: Ensuring Electronics Safety

- Benefits and Applications of CNC Machining in Holland, Ohio

Understanding CNC Machining for Energy-Efficient Packaging

CNC machining has emerged as a game-changer in the realm of energy-efficient packaging, particularly when it comes to safeguarding delicate items like electronic components. By utilizing advanced computer-controlled machines, manufacturers can create precise and customized protective foam inserts tailored to specific product needs. These custom foam inserts are designed to fit perfectly within packaging materials, providing superior shock absorption and preventing damage during transportation.

For industries in Holland, Ohio, focusing on electronics assembly or distribution, the benefits are clear. ESD-safe foam inserts, for instance, play a vital role in maintaining the integrity of static-sensitive components. These anti-static foams ensure that electrical charges are dissipated safely, reducing the risk of damage to delicate circuit boards and semiconductors. With the right CNC machining techniques, companies can produce these specialized foam inserts efficiently, contributing to overall energy efficiency by minimizing material waste and optimizing packaging designs for better resource utilization.

The Role of Protective Foam Inserts in Electronics Packaging

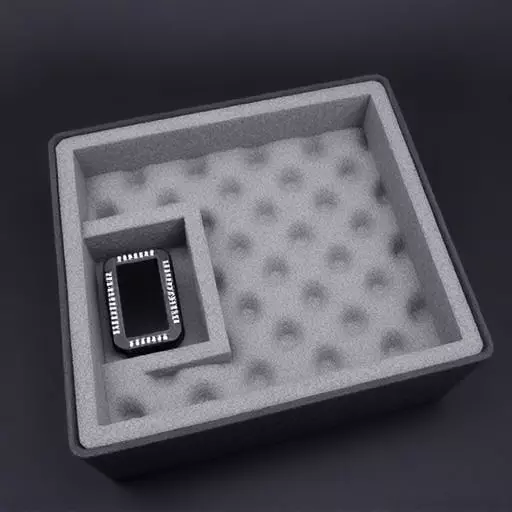

Protective foam inserts play a pivotal role in ensuring the safe transportation and storage of electronic components, especially in complex packaging scenarios. These specialized inserts are designed to fit snugly within packaging containers, providing a shock-absorbing and anti-static barrier for delicate electronics. In the competitive market for energy-efficient packaging solutions, custom foam inserts offer a tailored approach, catering to specific product dimensions and requirements.

For instance, ESD (Electrostatic Discharge) safe foam inserts are crucial in preventing damage to sensitive electronic parts. These inserts utilize materials that dissipate static electricity, safeguarding components from potentially destructive sparks. In the case of protective foam inserts for electronics in Holland, Ohio, local manufacturers offer advanced solutions, incorporating innovative foams and designs to meet industry standards. This ensures that electronic devices, regardless of their size or shape, arrive at their destination in optimal condition, contributing to overall energy efficiency by minimizing damage and waste during packaging and transportation.

Custom Foam Inserts: Tailoring Solutions for Specific Needs

Custom Foam Inserts play a pivotal role in enhancing energy efficiency within packaging, particularly for sensitive electronic components. These tailored solutions, often crafted from protective foam materials, offer specialized support and shielding. In the case of electronics in Holland, Ohio, businesses have leveraged custom foam inserts to create ESD-safe (Electrostatic Discharge) environments, ensuring that anti-static foam protects valuable hardware during transport and storage.

By designing these inserts to exacting specifications, manufacturers can address unique challenges posed by various electronic devices. Whether it’s a matter of absorbing shocks, preventing damage from vibrations, or maintaining optimal temperature control, custom foam inserts provide tailored solutions. This level of customization ensures that energy-efficient packaging meets the specific needs of diverse electronic products, contributing to reduced waste and enhanced product lifespan.

ESD-Safe and Anti-Static Foams: Ensuring Electronics Safety

ESD-Safe and Anti-Static Foams play a critical role in protecting sensitive electronic components during packaging and transportation. In an industry where static electricity can cause significant damage, these specialized foams are essential. ESD-Safe foam inserts for electronics in Holland, Ohio, and beyond, are designed to minimize the risk of electrostatic discharge (ESD), ensuring that delicate devices arrive at their destination intact.

Custom foam inserts offer a tailored solution, accommodating various electronic shapes and sizes while providing superior anti-static protection. These foams are crafted from materials that safely dissipate static buildup, preventing it from reaching critical components. By incorporating ESD-safe and anti-static foam in packaging designs, manufacturers can safeguard their products, reducing the likelihood of costly repairs or replacements due to ESD-related damage.

Benefits and Applications of CNC Machining in Holland, Ohio

CNC machining offers a multitude of benefits for energy-efficient packaging in Holland, Ohio. One of its key strengths lies in the precision and customization it provides. Local manufacturers can create complex geometric shapes and precise dimensions for protective foam inserts designed specifically for electronics, such as those used in the production of ESD-safe (Electrostatic Discharge) foam inserts. This level of customization ensures that every electronic device is securely padded, minimizing damage during transit.

Additionally, CNC machining allows for the efficient production of custom foam inserts at a lower environmental cost. By optimizing material use and reducing waste, these processes contribute to energy conservation and sustainable packaging practices. The application of anti-static foam for electronics in Holland, Ohio, becomes not only an effective solution for product protection but also an eco-friendly choice, aligning with the region’s commitment to sustainability and innovation in manufacturing.