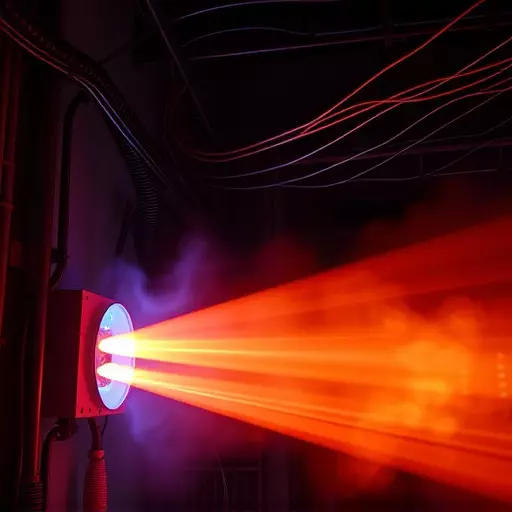

The arc flash study process is a meticulous methodology for evaluating and mitigating electrical hazards within industrial facilities, essential for adhering to arc flash safety standards. It begins with a comprehensive risk assessment identifying potential arc flash risks, followed by engineering analyses of circuit configurations and fault scenarios. Calculations determine arcing current levels and energy release, guiding the selection of suitable personal protective equipment (PPE) and system enhancements. The process concludes with a detailed report outlining findings and recommendations for a tailored arc flash protection plan. Electrical hazard analysis, involving circuit configuration examinations and component ratings, significantly enhances arc flash safety by categorizing risks based on severity and likelihood, leading to strategic safety measures like enhanced grounding systems and PPE selection.

“In the realm of industrial safety, understanding and managing arc flash risks is paramount. This comprehensive article delves into advanced techniques for arc flash analysis, a critical process in electrical hazard assessment. We explore the step-by-step methodology of an arc flash study process, highlighting its role in identifying potential dangers. Furthermore, we examine electrical hazard analysis methods, providing insights into risk mitigation strategies. Additionally, the article elucidates arc flash safety standards and best practices for ensuring compliance and enhancing worker protection.”

- Arc Flash Study Process: Unraveling the Step-by-Step Methodology

- Electrical Hazard Analysis: Identifying Risks and Mitigating Potential Dangers

- Arc Flash Safety Standards: Compliance and Best Practices for Enhanced Protection

Arc Flash Study Process: Unraveling the Step-by-Step Methodology

An arc flash study process is a systematic approach to evaluating and mitigating electrical hazards within industrial facilities, essential in ensuring arc flash safety standards. This meticulous methodology involves several critical steps. Initially, risk assessment forms the cornerstone by identifying potential arc flash risks across various systems and equipment. Here, engineers analyse circuit configurations, fault scenarios, and available protective devices.

Subsequently, detailed calculations are performed to determine arcing current levels and energy release, using equations and software tools designed for this purpose. This data informs the selection of appropriate personal protective equipment (PPE) and system improvements. The process culminates in a comprehensive report outlining findings, recommendations, and a detailed arc flash protection plan tailored to the facility’s unique needs.

Electrical Hazard Analysis: Identifying Risks and Mitigating Potential Dangers

Electrical Hazard Analysis is a critical step in ensuring arc flash safety within industrial environments. This methodical process involves identifying potential risks associated with electrical systems and equipment, focusing on those that could lead to an arc flash event. By thoroughly examining circuit configurations, component ratings, and operational parameters, professionals can pinpoint areas of concern. Advanced arc flash study processes utilize sophisticated software and simulation tools to model real-world scenarios, enabling accurate risk assessment. These studies go beyond simple compliance with arc flash safety standards, aiming to mitigate potential dangers before they escalate.

Through detailed analysis, risks can be categorized based on severity and likelihood, guiding the implementation of appropriate safety measures. This proactive approach allows for the development of customized protection strategies, including strategic equipment placement, enhanced grounding systems, and personal protective equipment (PPE) selection tailored to specific tasks. By integrating these measures into the electrical hazard analysis framework, organizations can significantly reduce the risk of arc flash incidents, fostering a safer working environment.

Arc Flash Safety Standards: Compliance and Best Practices for Enhanced Protection

Arc Flash Safety Standards play a pivotal role in ensuring the well-being of workers and compliance with regulatory requirements. These standards guide the implementation of robust safety measures, particularly in high-risk industries where electrical hazards are prevalent. Compliance involves adhering to stringent guidelines that encompass the entire arc flash study process, from risk assessment to protective equipment selection.

Best practices dictate a comprehensive approach, including regular electrical hazard analysis, up-to-date training for personnel, and adherence to industry-specific standards. By prioritizing these safety standards, organizations can mitigate risks effectively, ensuring a safer working environment. This proactive measure not only protects employees but also fosters a culture of safety awareness and compliance.