In Holland, Ohio's vibrant packaging industry, CNC (Computer Numerical Control) machining is revolutionizing equipment storage and organization. Custom CNC-machined packaging components offer unparalleled precision, efficiency gains, reduced lead times, improved product quality, and complex geometric shapes, positioning local businesses at the forefront of their market. This advanced technology enhances operational efficiency, reduces errors, increases durability, and enables intricate designs previously unattainable with traditional methods, making it a game-changer in modern packaging needs, from product protection to aesthetic enhancement. Custom steel racks, engineered to meet specific storage needs, further optimize floor space and support heavy machinery, catering to the evolving CNC machining technologies in the region's packaging sector.

“In Holland, Ohio, the packaging industry has embraced cutting-edge technology with the integration of CNC (Computer Numerical Control) machining. This article delves into the world of CNC machining for packaging, exploring its significance and custom solutions. From understanding the intricacies of CNC machining to unlocking efficiency through its benefits, we highlight how this process revolutionizes packaging components. Furthermore, we introduce steel racks as essential infrastructure, facilitating seamless integration of industrial equipment.”

- Understanding CNC Machining for Packaging Industry in Holland, Ohio

- Custom CNC-Machined Packaging Components: A Closer Look

- Unlocking Efficiency with Benefits of CNC Machining in Packaging

- Steel Racks: The Essential Infrastructure for Industrial Equipment Integration

Understanding CNC Machining for Packaging Industry in Holland, Ohio

The steel racks designed for industrial equipment often play a pivotal role in the efficient functioning of manufacturing units, and Holland, Ohio, is no exception. In this vibrant packaging industry, CNC (Computer Numerical Control) machining has emerged as a game-changer. This advanced technology offers unparalleled precision and customization, catering to the intricate needs of package design and production. By employing custom CNC-machined packaging components, manufacturers in Holland can achieve remarkable efficiency gains.

CNC machining for the packaging industry provides numerous benefits, including reduced lead times, improved product quality, and the ability to create complex geometric shapes. This technology ensures that every component is manufactured with meticulous accuracy, fitting seamlessly into the overall packaging system. As a result, businesses in Holland, Ohio, can stay ahead of the competition by offering tailored solutions to their clients, ultimately enhancing their market position.

Custom CNC-Machined Packaging Components: A Closer Look

In the realm of industrial equipment storage and organization, custom CNC-machined packaging components are emerging as a game-changer. Located in Holland, Ohio, businesses are leveraging advanced CNC machining technologies to create sophisticated and tailored solutions for their unique packaging needs. This innovative approach offers numerous benefits, particularly within the fast-paced and demanding environment of the packaging industry.

CNC machining allows for precise engineering and customization, ensuring that every component is meticulously designed to fit specific equipment dimensions and requirements. By utilizing this method, manufacturers can achieve enhanced efficiency, as these custom parts streamline the packing process, reduce manual labor, and minimize errors. Moreover, CNC-machined components are known for their durability and precision, contributing to longer-lasting storage racks and overall system reliability. These benefits, coupled with the ability to adapt to evolving packaging trends, make CNC machining a preferred choice for businesses seeking cutting-edge solutions in Holland, Ohio, and beyond.

Unlocking Efficiency with Benefits of CNC Machining in Packaging

In today’s competitive packaging industry, Holland Ohio is witnessing a significant shift towards adopting advanced technologies to enhance efficiency and product quality. CNC machining for packaging plays a pivotal role in this transformation, offering unparalleled precision and customization. By leveraging custom CNC-machined packaging components, manufacturers can unlock a range of benefits that drive operational excellence.

The integration of CNC machining in the packaging process allows for intricate designs and complex geometries that were once unattainable with traditional methods. This level of customization ensures that every package is tailored to specific product requirements, resulting in improved protection during transportation and enhanced aesthetic appeal. Moreover, CNC machines can rapidly produce these components, reducing lead times significantly, which is crucial for meeting the fast-paced demands of modern supply chains.

Steel Racks: The Essential Infrastructure for Industrial Equipment Integration

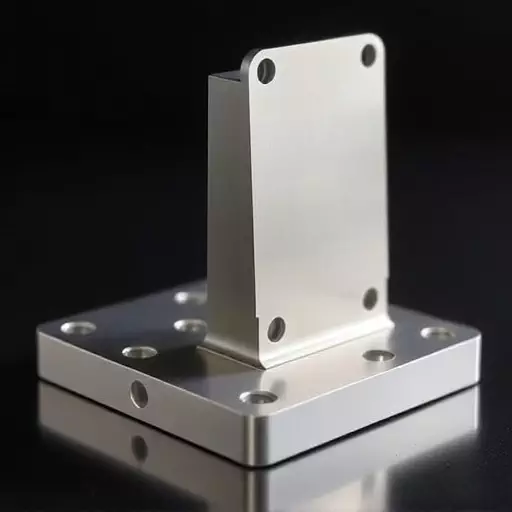

Steel racks are an essential infrastructure component for industrial equipment integration, especially in dynamic sectors like the packaging industry. In Holland, Ohio, where CNC machining plays a pivotal role, custom-engineered racks cater to the precise storage and organization needs of sophisticated machinery and components. These racks not only optimize floor space but also enhance operational efficiency by streamlining access and movement of equipment, such as CNC machines used for manufacturing packaging components.

The benefits of steel rack implementation are multifaceted. They offer robust support for heavy machinery, ensuring stability and safety in high-performance environments. Moreover, customizable design options allow businesses to tailor racks to specific requirements, accommodating unique dimensions and weights of custom CNC-machined packaging components. This flexibility is particularly advantageous in industries where innovation drives production, like the packaging sector in Holland, Ohio, where CNC machining technologies continue to evolve, pushing the boundaries of precision and efficiency.