Custom automotive foam inserts from Holland, Ohio, provide superior protection for fragile components during shipping. Tailored to specific part shapes and sizes, these multi-layer insulators minimize movement and absorb shock, ensuring the safe arrival of delicate items like glass, mirrors, and electrical systems. By preventing damage caused by chafing, cracks, or breaks, these foam inserts streamline shipping processes and reduce claims for damaged goods, maintaining product integrity.

“Discover the revolutionary power of multi-layer foam inserts in the automotive industry. This detailed overview explores how these innovative solutions are transforming shipping and protection for delicate automotive parts. From ‘automotive foam inserts for shipping Holland Ohio’ to tailored ‘custom automotive foam inserts’, we delve into their versatility and safety benefits. Learn how these advanced materials ensure the secure transportation of fragile components, making them an indispensable tool for modern auto manufacturing.”

- Understanding Multi-layer Foam Inserts: A Detailed Overview

- Customization and Applications in Automotive Shipping

- Ensuring Safety for Fragile Automotive Parts with foam inserts

Understanding Multi-layer Foam Inserts: A Detailed Overview

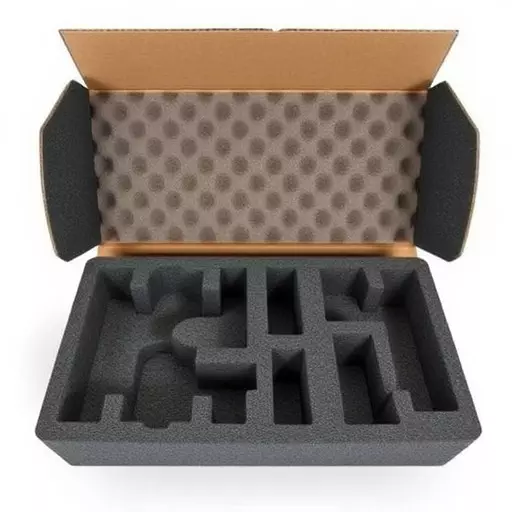

Multi-layer foam inserts are specialized packaging solutions designed to protect fragile and delicate items during shipping. These innovative products are particularly valuable in industries like automotive, where ensuring the safe transit of components is paramount. By understanding their structure and benefits, businesses in Holland, Ohio, and beyond can make informed decisions regarding shipping protection.

Custom automotive foam inserts are crafted with precision, incorporating multiple layers of lightweight yet robust materials. Each layer serves a specific purpose: one might provide cushioning, another may offer impact resistance, and additional layers could create a secure fit around various automotive parts. This multi-functional design is ideal for protecting fragile parts from rubs, bumps, and shocks during transportation. These inserts are especially crucial when shipping vulnerable automotive components, ensuring they arrive at their destination in pristine condition.

Customization and Applications in Automotive Shipping

Multi-layer foam inserts offer unparalleled customization options, making them ideal for protecting fragile automotive parts during shipping. These innovative solutions are tailored to specific part shapes and sizes, ensuring a perfect fit that minimizes movement and shock absorption. By employing custom automotive foam inserts, manufacturers can securely pack and transport delicate components, such as glass, mirrors, and intricate electrical systems, with enhanced confidence.

With a focus on precision engineering, companies in Holland, Ohio, specialize in creating these foam inserts for the automotive industry. Their expertise lies in understanding the unique challenges of shipping automotive parts, especially those that require specialized care. Custom foam inserts not only protect against physical damage but also prevent the shifting and rattling that can occur during transit, ensuring the safe arrival of valuable and fragile automotive components.

Ensuring Safety for Fragile Automotive Parts with foam inserts

In the world of automotive shipping and handling, ensuring the safe arrival of delicate components is paramount. This is where custom automotive foam inserts play a pivotal role. These specialized insulators are meticulously designed to safeguard fragile parts during transit, whether they’re being shipped across states or within the bustling halls of an Ohio distribution center. By offering a customized fit around each part, these foam inserts minimize movement and shock absorption, significantly reducing the risk of damage.

For instance, in Holland, Ohio, automotive plants and warehouses rely on such innovative packaging solutions to protect high-value components like glass, mirrors, and sensors. The custom nature of these foam inserts ensures they conform precisely to the shape and size of the parts they cradle, providing a secure environment that prevents chafing, cracks, or breaks. This not only maintains the integrity of the products but also streamlines the shipping process by reducing claims for damaged goods.