Arc flash, a severe electrical hazard from sudden energy release in high-voltage systems, requires a comprehensive arc flash study process. This involves analyzing equipment design, operating procedures, and maintenance to identify potential arc flash points. Adhering to safety standards like NFPA 70E or IEC 61508 guides risk mitigation strategies, including protective equipment, protocols, and training. Electrical hazard analysis is vital for identifying risks, creating tailored strategies, and ensuring compliance with global safety guidelines. Regular reviews maintain workplace safety around high-voltage systems.

In the realm of high-voltage systems, understanding and prioritizing arc flash safety is paramount. This comprehensive guide delves into critical aspects of arc flash prevention, encompassing ‘Understanding Arc Flash’, a detailed look at its definition and causal factors. We provide a step-by-step ‘Arc Flash Study Process’ for thorough risk assessment. ‘Electrical Hazard Analysis’ identifies risks within high-voltage systems, while exploring global ‘Arc Flash Safety Standards’ ensures compliance. Effective mitigation strategies are outlined, empowering professionals to safeguard against this potent electrical hazard.

- Understanding Arc Flash: Definition and Causes

- The Arc Flash Study Process: A Step-by-Step Guide

- Electrical Hazard Analysis: Identifying Risks in High-Voltage Systems

- Global Arc Flash Safety Standards and Regulations

- Implementing Effective Arc Flash Mitigation Strategies

Understanding Arc Flash: Definition and Causes

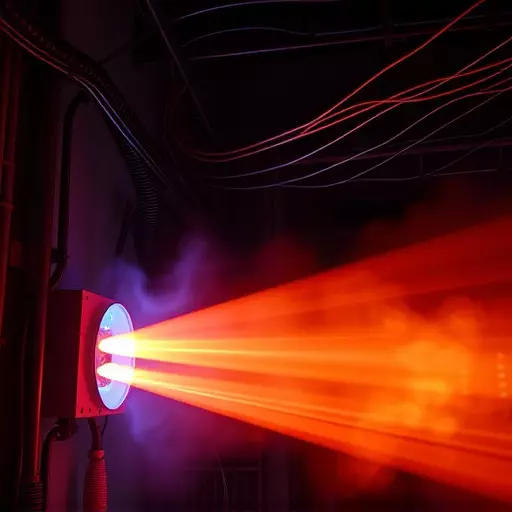

Arc flash is a significant electrical hazard that occurs in high-voltage systems when an electric arc forms between conductors or between a conductor and ground. This sudden release of energy can result in severe burns, damage to equipment, and even fatalities. Understanding arc flash involves delving into its definition and causes.

The arc flash study process includes a thorough analysis of the electrical system to identify potential arc flash scenarios. This involves evaluating components like switches, connectors, and insulation to determine their role in arcing events. By combining this analysis with an assessment of human exposure paths, professionals can establish appropriate arc flash safety standards to protect workers and minimize risks associated with electrical hazards.

The Arc Flash Study Process: A Step-by-Step Guide

The Arc Flash Study Process begins with a thorough electrical hazard analysis. This involves identifying all potential arc flash points within the high-voltage system, considering equipment design, operating procedures, and maintenance practices. By evaluating each component’s risk level, from live parts to faulted conductors, experts can pinpoint areas requiring enhanced safety measures.

Following this analysis, stakeholders should refer to established arc flash safety standards such as NFPA 70E or IEC 61508 for guidance on acceptable risk levels and mitigating strategies. This may include implementing protective equipment requirements, developing arc flash prevention protocols, and ensuring proper training for all personnel involved in the system’s design, installation, and maintenance.

Electrical Hazard Analysis: Identifying Risks in High-Voltage Systems

Electrical Hazard Analysis is a critical step in ensuring arc flash safety within high-voltage systems. It involves a meticulous process to identify potential risks and hazards associated with electrical equipment, particularly in industrial settings. By conducting an arc flash study process, professionals can assess the likelihood and consequences of an arc flash event, which are powerful and dangerous electrical discharges that occur when voltage gaps are closed.

This analysis considers factors such as system design, component age, maintenance history, and operational procedures to create a comprehensive understanding of the facility’s unique risks. Armed with this knowledge, organizations can implement tailored strategies, adhering to established arc flash safety standards, to mitigate risks and protect workers and infrastructure from severe electrical hazards.

Global Arc Flash Safety Standards and Regulations

The global arc flash safety landscape is governed by a myriad of standards and regulations, each aiming to mitigate electrical hazards in high-voltage systems. These guidelines are pivotal for ensuring worker safety and compliance across diverse industries. The arc flash study process, which involves a thorough Electrical Hazard Analysis (EHA), forms the backbone of these safety measures. By systematically evaluating potential arc flash risks, organizations can implement tailored strategies to protect personnel and equipment.

International standards bodies like IEC, ANSI, and NEC have played a significant role in harmonizing arc flash safety standards globally. These regulations mandate specific protective measures, such as appropriate personal protective equipment (PPE), clearance distances, and ground fault protection, among others. Adhering to these standards is not only a legal requirement but also ensures that high-risk electrical work is performed securely, minimizing the risk of severe injuries caused by arc flashes.

Implementing Effective Arc Flash Mitigation Strategies

Implementing effective arc flash mitigation strategies is a multifaceted process that begins with a comprehensive arc flash study process. This involves a detailed analysis of existing electrical systems to identify potential arc flash hazards. By employing advanced tools and techniques, such as fault current calculations and thermal modeling, professionals can pinpoint high-risk areas. An arc flash study process not only identifies dangers but also recommends tailored solutions based on industry-recognized arc flash safety standards.

These standards, developed by organizations like the National Fire Protection Association (NFPA), provide guidelines for minimizing the impact of arc flashes. Solutions might include implementing engineering controls, such as proper grounding and shielding, or using personal protective equipment (PPE). Regular reviews and updates to these strategies ensure ongoing compliance with electrical hazard analysis findings, enhancing workplace safety and reducing risks associated with high-voltage systems.