when addressing infrastructure maintenance, pavement milling and grinding stands out as a critical yet specialized operation. This article delves into the intricacies of mastering this process in Toledo, Ohio, offering insights through a series of sections that cover everything from optimizing operations to ensuring safety and compliance, all while emphasizing cost efficiency and superior pavement quality. From selecting the best milling patterns to leveraging advanced techniques, readers will gain a comprehensive understanding of pavement milling and grinding best practices, making this guide an indispensable resource for professionals in the field.

- Optimizing Pavement Milling and Grinding Operations: A Comprehensive Guide

- Understanding the Equipment Essential for Efficient Milling and Grinding in Toledo, Ohio

- Best Practices in Milling Pattern Selection for Optimal Pavement Resurfacing

- Ensuring Safety and Compliance During Pavement Milling and Grinding Activities

- Advanced Techniques in Milling and Grinding for Superior Pavement Quality

- Maximizing Cost Efficiency and Resource Management in Pavement Milling and Grinding Projects

Optimizing Pavement Milling and Grinding Operations: A Comprehensive Guide

Infrastructure maintenance and development are critical for the safety and efficiency of transportation networks. Pavement milling and grinding are essential processes within this domain, playing a significant role in roadway preparation and maintenance. These operations not only extend the life of existing pavements but also prepare surfaces for new asphalt overlays. To optimize pavement milling and grinding operations, it is crucial to consider several key factors. Proper equipment selection, including the right milling machines suited for the job, ensures efficient material removal and surface preparation. The choice between cold and hot milling methods depends on project requirements and environmental conditions; hot milling is often used for deeper milling applications, while cold milling is ideal for shallow milling or surface preparation tasks.

In Toledo, Ohio, these operations are conducted with precision and care to ensure the highest quality results. The city’s Department of Transportation, or DOT, employs advanced techniques and state-of-the-art technology to deliver superior milling services. Factors such as weather, material type, and project scope must be carefully managed to maintain optimal performance. Regular maintenance of the milling equipment, including blades and machinery, is essential to prevent downtime and ensure consistent output. By adhering to best practices in pavement milling and grinding, Toledo, Ohio sets a benchmark for other regions to follow, demonstrating a commitment to infrastructure excellence and long-term sustainability.

Understanding the Equipment Essential for Efficient Milling and Grinding in Toledo, Ohio

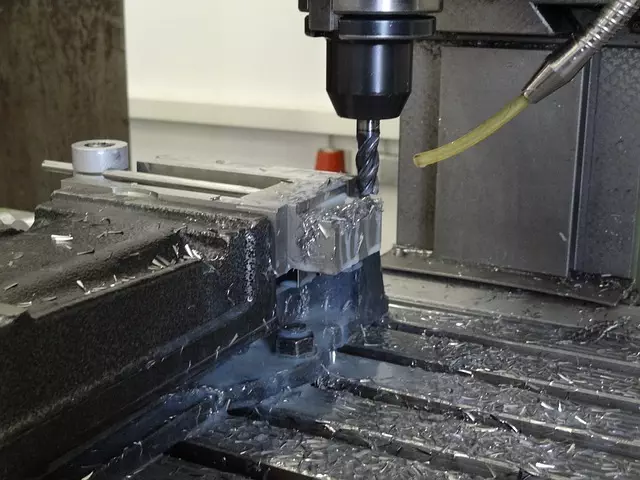

In Toledo, Ohio, the maintenance and renovation of infrastructure, particularly roadways, are critical for ensuring safe and efficient transportation networks. Pavement milling and grinding play a pivotal role in this process, enabling the removal of asphalt or concrete to prepare surfaces for repairs, resurfacing, or the creation of new roadways. To execute these tasks effectively, understanding the equipment essential for efficient milling and grinding is paramount. Key machinery includes milling machines, which are designed to remove material in precise patterns, and grinding machines, which smooth and level surfaces post-removal. These machines vary in size and capability, with some being compact and suitable for smaller jobs or tight spaces, while larger units can handle broader removal requirements. The choice of equipment is influenced by factors such as the depth and width of the material to be removed, the conditions of the pavement, and the desired finish.

In Toledo, Ohio, the city’s Department of Transportation (DOT) or contractors working on behalf of the DOT, utilize advanced milling and grinding equipment to maintain roadways efficiently. The process involves not only the physical removal of the pavement but also the efficient collection and recycling of the removed material, often incorporating it into new pavements as part of sustainable construction practices. The equipment used must be well-maintained and regularly calibrated to ensure precision and minimize disruptions to traffic flow. Additionally, operators must be trained in the safe and effective use of this machinery to maximize productivity while maintaining high safety standards. The integration of modern technology, such as GPS-guided systems for milling patterns and automation to control machine operations, further enhances the efficiency and accuracy of pavement milling and grinding activities in Toledo, Ohio. Understanding and utilizing the right equipment and technology is essential for the successful execution of these critical infrastructure projects.

Best Practices in Milling Pattern Selection for Optimal Pavement Resurfacing

When engaging in pavement milling and grinding as part of resurfacing projects, pattern selection plays a critical role in ensuring the longevity and quality of the finished surface. The process of pavement milling and grinding in Toledo, Ohio, or any region, involves carefully choosing milling patterns to accommodate the specific needs of the project, including traffic flow, subgrade conditions, and the intended pavement structure. A well-planned pattern enhances the efficiency of the milling operation while optimizing the durability and performance of the resurfaced pavement.

Factors such as the direction of milling relative to the existing pavement seams can influence the bond between the old and new layers, affecting both the structural integrity and the smoothness of the final pavement surface. Selecting the appropriate milling patterns requires an understanding of the material properties of the pavement being milled, as well as the equipment capabilities. Additionally, considering local climate conditions and anticipated traffic loads ensures that the selected pattern can withstand environmental stresses and heavy usage without premature failure. By adhering to best practices in pattern selection during pavement milling and grinding, contractors can achieve a high-quality finish that meets both project specifications and the expectations of the traveling public in Toledo, Ohio.

Ensuring Safety and Compliance During Pavement Milling and Grinding Activities

Operating within the realm of pavement milling and grinding demands stringent adherence to safety protocols and compliance with industry standards, especially when considering the intricate operations in locations such as Toledo, Ohio. Safety begins with a comprehensive pre-operation check that includes inspecting all machinery for potential hazards and ensuring equipment functionality. Workers must be equipped with personal protective equipment (PPE) such as high-visibility clothing, safety helmets, ear protection, and dust masks to safeguard against environmental risks and physical injuries.

In addition to personal protective measures, compliance with local, state, and federal regulations is paramount. This involves obtaining necessary permits, adhering to noise and dust ordinances, and maintaining environmental protections during milling activities. The use of advanced technology, such as GPS-guided milling machines, not only enhances precision and efficiency but also minimizes the impact on surrounding infrastructure. Regular training for personnel on the latest techniques and machinery is essential to maintain a high standard of operation and reduce the likelihood of accidents or operational errors. By prioritizing safety and compliance, pavement milling and grinding operations in Toledo, Ohio, can be conducted effectively and responsibly, ensuring project success and the well-being of all personnel involved.

Advanced Techniques in Milling and Grinding for Superior Pavement Quality

In the realm of infrastructure maintenance and development, pavement milling and grinding play a crucial role in achieving superior pavement quality. This process involves removing surface layers of asphalt or concrete to prepare for repairs, resurfacing, or construction projects. Advanced techniques in milling and grinding have significantly enhanced the precision and efficiency of this operation, leading to better outcomes for roadways. For instance, in Toledo, Ohio, the deployment of state-of-the-art machinery equipped with laser guidance systems ensures milled materials are removed to precise depths, minimizing waste and optimizing material reuse. These advanced systems facilitate a more controlled and accurate operation, which is essential for maintaining pavement structure integrity and longevity. Additionally, the integration of GPS technology allows for real-time adjustments during the process, ensuring a uniform milling pattern that contributes to the overall quality and safety of the pavement surface.

The commitment to excellence in pavement milling and grinding in Toledo, Ohio, extends beyond the use of sophisticated equipment. It encompasses a comprehensive approach that includes rigorous operator training, adherence to stringent safety protocols, and meticulous project planning. This holistic strategy not only enhances worker safety but also ensures the highest quality standards for the milled surfaces. The end result is a smooth, durable pavement surface that contributes to the longevity of the road infrastructure and the overall driving experience. The advanced techniques employed in Toledo exemplify the dedication to maintaining and improving roadways, setting a benchmark for other regions to follow in the pursuit of superior pavement quality through pavement milling and grinding.

Maximizing Cost Efficiency and Resource Management in Pavement Milling and Grinding Projects

In pavement milling and grinding operations, achieving cost efficiency and effective resource management is paramount for the success of a project. To optimize costs in pavement milling and grinding, contractors must employ strategies that balance precision with productivity. Utilizing advanced machinery that enhances both speed and accuracy can significantly reduce the time required to mill asphalt surfaces while ensuring minimal waste. In Toledo, Ohio, for instance, where such projects are common, the selection of the right milling machine—one that is well-maintained and appropriately matched to the project’s specific requirements—is crucial. Preparation and planning before commencing work help in predicting costs and mitigating risks associated with unforeseen conditions. This proactive approach extends to resource allocation, where scheduling the right equipment and skilled personnel at the right time can prevent delays and overtime expenses. Furthermore, by closely monitoring material usage and machine performance during the milling process, contractors can adjust their operations in real-time to avoid unnecessary expenditures. In doing so, they adhere to the best practices in pavement milling and grinding, ensuring that projects like those carried out in Toledo, Ohio, are completed not only within budget but also with a high degree of quality and efficiency.