Backflow preventers, particularly RPZ (Reduced Pressure Zone) models, are vital for protecting potable water supplies in industrial settings from contamination. In Fayetteville, certified commercial backflow preventer installation is both a regulatory requirement and a critical step towards safeguarding workers, communities, and the environment. These advanced devices automatically shut off when detecting reverse water flow, preventing hazardous substances from mixing with the main supply. Proper installation, maintenance, and adherence to local health regulations ensure a secure industrial water system, compliance with standards, and peace of mind for business owners.

In the world of industrial safety, understanding backflow preventers is paramount. These devices play a crucial role in preventing contaminants from flowing backward into potable water supplies, ensuring the integrity of water systems. For businesses in Fayetteville seeking certified commercial backflow preventer installation, this article offers an indispensable guide. We explore RPZ backflow preventer setup tailored for industrial sites, along with essential post-installation maintenance tips to ensure longevity and compliance.

- Understanding Backflow Preventers: Their Role in Industrial Safety

- The Importance of Certified Commercial Installation

- RPZ Backflow Preventer Setup: A Step-by-Step Guide for Industrial Sites

- Ensuring Longevity and Compliance: Post-Installation Maintenance Tips

Understanding Backflow Preventers: Their Role in Industrial Safety

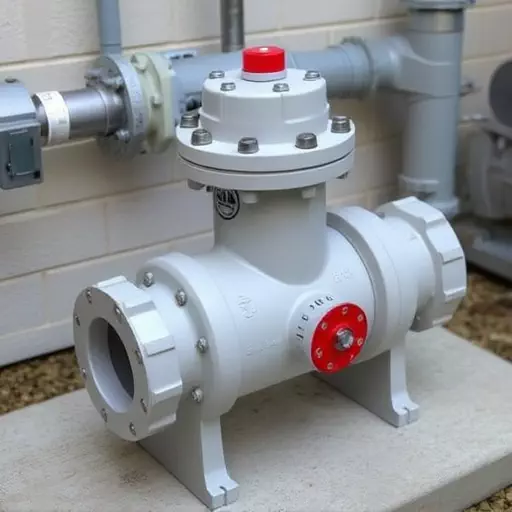

Backflow preventers are critical safety devices used to stop contaminants from flowing back into potable water supplies, ensuring the purity and safety of water in industrial settings. In Fayetteville, certified commercial backflow preventer installation is not just a regulatory requirement but also a vital step towards protecting workers and communities. These devices operate by automatically shutting off when they detect the reverse flow of water, preventing any potential harm caused by hazardous substances mingling with the main water supply.

Industrial sites, with their diverse operations and complex plumbing systems, often pose unique challenges for backflow prevention. RPZ (Reduced Pressure Zone) backflow preventers are specifically designed to meet these demands, offering advanced protection against both physical and chemical contaminants. Proper installation and regular maintenance of these devices are essential, as they safeguard the integrity of water systems and comply with local health department regulations, ensuring a secure environment for industrial operations in Fayetteville.

The Importance of Certified Commercial Installation

In industrial settings where the safety and integrity of water systems are paramount, certified commercial backflow preventer installation cannot be overstated. The correct setup of a RPZ (Reduced Pressure Zone) backflow preventer is crucial to safeguarding against contamination and ensuring the quality of water supply in Fayetteville and beyond. Professional installers with expertise in backflow preventer installation ensure that these devices operate optimally, mitigating the risk of hazardous backflow events.

A certified commercial installation guarantees compliance with local regulations and standards, offering peace of mind for business owners. This meticulous process involves assessing the specific needs of each industrial site, selecting the appropriate backflow preventer models, and configuring them to meet the unique challenges posed by various fluids and pressures. By entrusting this task to experts, businesses can prevent costly damage, maintain operational continuity, and protect both their employees and the environment.

RPZ Backflow Preventer Setup: A Step-by-Step Guide for Industrial Sites

When it comes to protecting your industrial facility from contaminated water flow, a RPZ (Reducing Pressure Zone) backflow preventer setup is essential. Here’s a straightforward, step-by-step guide for installing this crucial component in Fayetteville, ensuring a certified commercial backflow preventer installation that safeguards your operations:

1. Location Identification: Begin by identifying the suitable location for the RPZ device, typically near the water source or where the potential for backflow is highest. Ensure it’s accessible for maintenance and testing.

2. Device Selection: Choose a RPZ backflow preventer certified for industrial use, considering factors like pressure rating, flow capacity, and compatibility with your existing plumbing system. Verify that it complies with local codes and regulations in Fayetteville.

3. Installation Preparation: Turn off the water supply to the affected area. Drain any residual water from the lines to facilitate a clean installation. Gather necessary tools, including a wrench set, pipeline cutter, and safety gear.

4. Physical Installation: Cut the pipes according to the manufacturer’s instructions and install the RPZ preventer, ensuring proper connections and sealing. Use thread sealants if needed to prevent leaks.

5. Testing and Verification: After installation, test the device to ensure it operates as expected. Check for any leaks and confirm that water flow is restricted under backpressure conditions. Verify compliance with local testing protocols in Fayetteville.

6. Documentation and Maintenance Planning: Keep detailed records of the installation process, including dates, model numbers, and tester results. Schedule regular maintenance checks to ensure optimal performance and longevity of your RPZ backflow preventer.

Ensuring Longevity and Compliance: Post-Installation Maintenance Tips

After successfully completing a certified commercial backflow preventer installation, such as an RPZ backflow preventer setup for industrial sites in Fayetteville, proper post-installation maintenance is paramount to ensure longevity and compliance with local regulations. Regular inspections are crucial to identify any potential issues or leaks that may arise over time. These checks should include verifying the integrity of connections, inspecting gaskets, and ensuring all components remain tightly secured.

Proper documentation, including maintaining records of installation details and maintenance activities, is essential for future reference and regulatory audits. Additionally, following manufacturer guidelines for fluid compatibility and pressure ratings will help extend the lifespan of the backflow preventer. By adhering to these maintenance practices, industrial facilities can maintain a safe water supply and meet local code requirements related to backflow prevention in Fayetteville.