CNC machining in Holland, Ohio, is transforming the packaging industry by offering precise, custom-designed components that enhance product protection during shipping. This technology streamlines production, ensures accuracy, and creates durable steel racks for long-distance transit, benefiting manufacturers and retailers with cost savings, quality control, and innovative design. By adopting CNC machining, companies can revolutionize their packaging, making it more efficient, sustainable, and protective of valuable goods.

In today’s globalized world, efficient and durable packaging solutions are paramount for long-distance shipping. Ohio, particularly Holland, has emerged as a hub for innovative practices, with CNC machining playing a pivotal role in transforming the packaging industry. This article explores how custom CNC-machined components enhance logistics, focusing on steel racks designed for durability during transit. We’ll delve into the benefits, real-world applications, and sustainable future of these advanced packaging solutions, highlighting the rise of CNC machining in Holland, Ohio.

- The Rise of CNC Machining in Packaging: A Holland, Ohio Perspective

- Customization and Efficiency: How CNC-Machined Components Transform the Industry

- Steel Racks for Shipping: Durability Meets Logistics

- Benefits of Durable Steel Racks for Long-Distance Transport

- Case Studies: Real-World Applications of CNC Machining in Packaging Shipment

- The Future of Sustainable Packaging: Exploring Innovative Solutions

The Rise of CNC Machining in Packaging: A Holland, Ohio Perspective

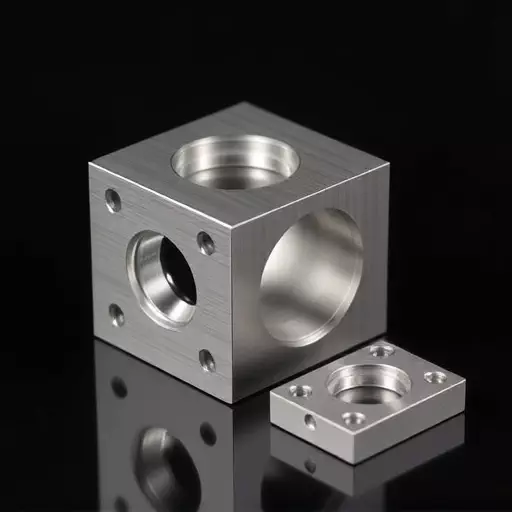

In Holland, Ohio, there’s been a notable shift in the packaging industry, driven by the rapid adoption of Computer Numerical Control (CNC) machining. This innovative technology is transforming how custom cnc-machined packaging components are designed and produced, offering a multitude of benefits to manufacturers and retailers alike. CNC machining for packaging industry Holland, Ohio, has enabled the creation of intricate and precise parts, enhancing product protection during long-distance shipping.

One of the key advantages lies in its ability to streamline production processes, reducing lead times significantly. This is particularly crucial for businesses dealing with fast-paced markets where quick turnaround times are essential. Moreover, CNC machining provides unparalleled accuracy, ensuring every packaging component meets strict quality standards. As a result, durable steel racks designed for long-distance shipping can be crafted with meticulous care, contributing to the overall reliability and safety of goods during transit.

Customization and Efficiency: How CNC-Machined Components Transform the Industry

In today’s competitive shipping landscape, efficient and durable packaging solutions are paramount. Customization plays a pivotal role, with many companies now turning to advanced manufacturing techniques like CNC machining for a competitive edge. By employing CNC-machined components, particularly in the packaging industry in Holland, Ohio, businesses can achieve unparalleled precision and complexity in their product design. This technology allows for the creation of custom cnc-machined packaging components that perfectly cater to unique product requirements, ensuring optimal protection during long-distance shipping.

The benefits of CNC machining in packaging are vast. It revolutionizes production by enabling rapid prototyping and small batch runs, allowing companies to quickly adapt to market demands. Moreover, CNC machining guarantees consistent quality and repeatability, ensuring every component meets strict specifications. This precision results in sturdier, more reliable packaging, reducing damage during transit and enhancing customer satisfaction. The efficiency gains from automated CNC processes also translate into cost savings for businesses, making it a game-changer for the industry.

Steel Racks for Shipping: Durability Meets Logistics

In today’s globalized market, efficient logistics are key to success. Durable steel racks play a pivotal role in this aspect, especially for long-distance shipping. These racks, often designed with precision CNC machining, offer unparalleled sturdiness and versatility. Companies in Holland, Ohio, specializing in CNC machining for the packaging industry, cater to these demands by creating custom cnc-machined packaging components tailored to specific needs.

The benefits of integrating CNC machining into packaging are multifaceted. It ensures that every rack is meticulously crafted, meeting exacting standards for load-bearing capacity and structural integrity. This precision not only enhances safety during transit but also optimizes space utilization within shipping containers. Moreover, custom CNC-machined components can incorporate innovative designs, ensuring products arrive undamaged while reducing overall transportation costs.

Benefits of Durable Steel Racks for Long-Distance Transport

Durable steel racks offer significant advantages for long-distance shipping, ensuring the safe and efficient transport of goods across vast distances. One of the key benefits is their superior strength and sturdiness. These racks are designed to withstand extreme conditions, including rigorous handling during transit, making them ideal for fragile or valuable items that require extra protection. Custom CNC machining plays a pivotal role in enhancing these racks’ functionality. In Holland, Ohio, for instance, companies specializing in CNC machining for the packaging industry can create intricate and precise components tailored to specific product needs.

This level of customization means that packaging solutions can be optimized for various goods, ensuring optimal space utilization and reducing potential damage. Custom cnc-machined packaging components not only enhance structural integrity but also allow for innovative design features. The benefits of CNC machining in the packaging sector are evident, from improved product security to efficient material use. This technology revolutionizes long-distance shipping by providing reliable, durable steel racks that meet the unique requirements of different industries.

Case Studies: Real-World Applications of CNC Machining in Packaging Shipment

The CNC machining for packaging industry Holland Ohio has revolutionized how companies prepare their products for long-distance shipping, showcasing the benefits of CNC machining in packaging. This advanced manufacturing process allows for the creation of custom CNC-machined packaging components tailored to specific product needs and design requirements. By leveraging computer-aided design (CAD) software, manufacturers can produce intricate parts with precision and efficiency.

Case studies demonstrate that integrating CNC machining into packaging solutions offers numerous advantages. For instance, it enables the production of lightweight yet robust packaging materials, reducing overall shipping costs and environmental impact. Moreover, CNC machines ensure consistent quality and accuracy, minimizing waste and maximizing product protection during transit. This is particularly valuable for fragile or high-value items, ensuring they arrive at their destinations safely and intact.

The Future of Sustainable Packaging: Exploring Innovative Solutions

The future of sustainable packaging is here, and it involves innovative solutions that blend durability with eco-friendliness. Durable steel racks, for instance, are gaining traction in long-distance shipping due to their longevity and recyclability—key attributes in reducing the environmental impact of transportation. As the demand for eco-conscious options continues to rise, industries like CNC machining in Holland, Ohio, are stepping up to meet these demands.

Custom CNC-machined packaging components offer a multitude of benefits, from precise design control to efficient production times. These advanced manufacturing techniques enable the creation of unique, tailored solutions that optimize space and weight, thereby reducing fuel consumption during shipping. By embracing such innovations, businesses not only contribute to a greener planet but also enhance their product presentation and overall brand image.