Process Hazard Analysis (PHA) lifecycle management is a strategic approach to hazard assessment and mitigation throughout a product or process's lifespan, using specialized pha facilitation tools and hazard identification techniques. PHA facilitation experts navigate complex industrial landscapes, leveraging their knowledge to guide organizations through robust risk management strategies. They employ advanced tools that streamline data collection, risk assessment, and strategy development, fostering efficient collaboration among stakeholders. Effective hazard identification methods, including checklists, scenario trees, fault tree analysis, and event sequence diagrams, ensure comprehensive examination of processes from raw material input to final product output. This proactive approach enables the implementation of robust safety measures, optimizing process design, operation, and maintenance for maximum safety and efficiency.

In today’s safety-conscious landscape, Process Hazard Analysis (PHA) is an indispensable tool for managing risks in complex industrial processes. This comprehensive guide delves into the intricate world of PHA lifecycle management, offering a detailed overview that spans from understanding its fundamentals to leveraging specialized pha facilitation experts and their cutting-edge tools. We also explore effective hazard identification techniques, underscoring their crucial role in successful PHA implementation.

- Understanding PHA Lifecycle Management: A Comprehensive Overview

- The Role of PHA Facilitation Experts and Their Tools

- Effective Hazard Identification Techniques for PHA Implementation

Understanding PHA Lifecycle Management: A Comprehensive Overview

PHA lifecycle management involves a systematic approach to identifying, evaluating, and mitigating hazards throughout the life of a product or process. It’s facilitated by experienced professionals who employ specialized tools and techniques, such as hazard identification methods, to ensure comprehensive risk assessment. This proactive strategy goes beyond compliance, aiming to optimize safety measures and enhance overall operational efficiency.

The process begins with thorough analysis using tools tailored for PHA facilitation, allowing experts to uncover potential risks hidden within complex systems. These techniques are crucial in identifying hazards that might be overlooked during initial design or routine maintenance checks. By systematically navigating through each phase of the lifecycle, organizations can implement effective risk management strategies, ensuring product and process safety from concept to retirement.

The Role of PHA Facilitation Experts and Their Tools

The Role of PHA Facilitation Experts and Their Tools

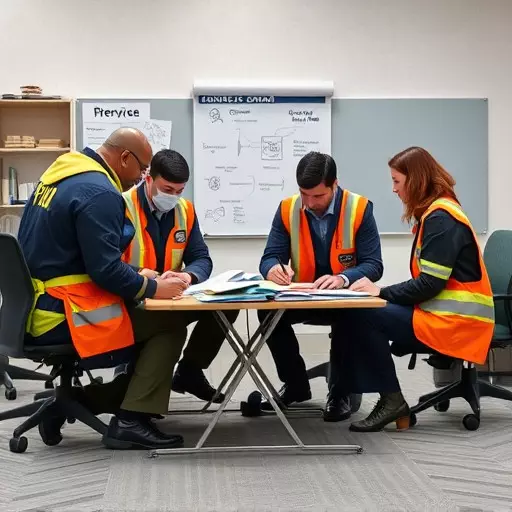

PHA facilitation experts play a pivotal role in navigating complex industrial landscapes, guiding organizations through effective hazard identification techniques. These professionals bring specialized knowledge and skills to ensure that Process Hazard Analysis (PHA) is conducted thoroughly and accurately. They act as navigators, helping teams to explore every aspect of potential risks within their operations, from design flaws to human error.

Through the use of advanced pha facilitation tools, these experts streamline the analysis process. These tools facilitate data collection, risk assessment, and mitigation strategy development. By employing structured methodologies and intuitive interfaces, they enable stakeholders to collaborate efficiently, ensuring that every voice is heard and every concern addressed. This collaborative approach enhances the overall effectiveness of PHA, ultimately contributing to enhanced process safety in industries worldwide.

Effective Hazard Identification Techniques for PHA Implementation

Effective hazard identification is a cornerstone of successful Process Hazard Analysis (PHA). PHA facilitation experts leverage a range of powerful tools and techniques to uncover potential risks within industrial processes. These include check lists, scenario trees, fault tree analysis, and event sequence diagrams. These methods encourage thorough examination of every step in the process, from raw material input to final product output, identifying both human errors and system failures that could lead to catastrophic events.

By combining these hazard identification techniques, PHA facilitation teams can create a comprehensive view of potential hazards, prioritize risks based on their likelihood and consequences, and develop effective mitigation strategies. This proactive approach allows for the implementation of robust safety measures, ensuring that processes are designed, operated, and maintained with maximum safety and efficiency in mind.