Expanded Polypropylene (EPP) molded foam packaging from Holland, Ohio, offers a revolutionary solution for industries seeking lightweight, strong, and fire-resistant packaging. Its unique structure reduces costs and environmental impact while providing exceptional shock absorption and superior thermal insulation. EPP's versatility allows customized designs for diverse products, enhancing safety during transportation and storage, especially in hazardous material sectors. These benefits make Holland, Ohio's EPP solutions a sustainable choice for industries worldwide.

“Unveiling the power of fire-resistant foam inserts: a game-changer in safety. This article explores the incredible capabilities of Expanded Polypropylene (EPP) Molded Foam Packaging from Holland, Ohio. Known for its lightweight nature, EPP foam offers much more than meets the eye. From enhancing product protection to providing exceptional fire resistance, these innovative solutions are transforming industries. Discover the benefits and explore diverse applications where Holland, Ohio’s EPP expertise truly shines, making it a go-to choice for smart packaging decisions.”

- Understanding EPP Foam: The Lightweight Wonder

- Fire Resistance: A Crucial Feature for Safety

- Benefits of Using EPP Molded Foam Packaging

- Applications: Where Holland, Ohio's EPP Solutions Shine

- Exploring Expanded Polypropylene Foam: Properties and Advantages

Understanding EPP Foam: The Lightweight Wonder

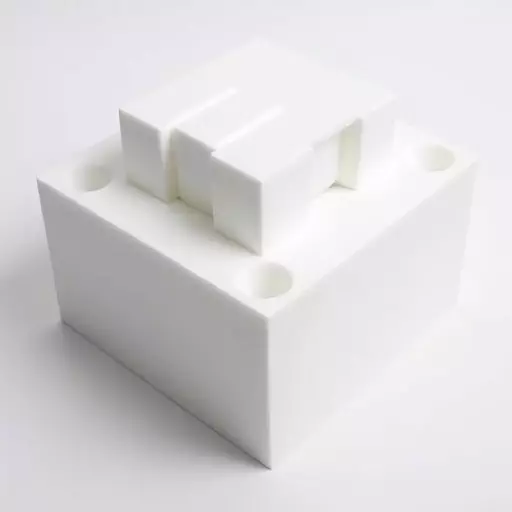

Expanded Polypropylene (EPP) foam is a lightweight wonder in the world of molded foam packaging. This innovative material has revolutionized various industries, including those in Holland, Ohio, and beyond, thanks to its unique properties. EPP is a closed-cell foam made from polypropylene resin, which undergoes a rapid expansion process creating tiny air pockets within the material. This structure provides exceptional strength-to-weight ratio, making it an ideal choice for packaging solutions.

The benefits of using EPP foam in packaging are numerous. Its lightweight nature reduces transportation costs and carbon footprint, while its excellent shock absorption properties protect fragile items during transit. Moreover, EPP is highly versatile, allowing for intricate designs and complex shapes to be molded with ease. With its superior fire resistance compared to other foam types, it offers enhanced safety for products that require protection from heat and flames. These characteristics make expanded polypropylene foam solutions a top choice for various applications, from protecting electronic gadgets to shipping delicate medical equipment.

Fire Resistance: A Crucial Feature for Safety

Fire resistance is a crucial feature in any packaging material, especially when it comes to lightweight EPP molded foam. In the event of a fire, traditional foams can contribute to the spread and intensity of the flames, posing significant risks to both people and property. However, EPP foam offers an effective solution with its inherent flame-resistant properties. This is particularly important for industries that handle flammable or hazardous materials, where packaging must not only protect the contents but also minimize the potential for fire hazards during transportation and storage.

The benefits of using EPP foam packaging are numerous. It acts as a barrier, slowing down the transfer of heat and flames, providing valuable time for evacuation and response. This is achieved through its unique expanded polypropylene (EPP) structure, which is designed to resist burning and melt, thus reducing the risk of fire spread. Such fire-resistant EPP foam solutions are widely available in Holland, Ohio, catering to various industries’ needs for lightweight yet robust packaging that ensures the safety of their operations and products.

Benefits of Using EPP Molded Foam Packaging

Using lightweight EPP molded foam packaging offers numerous advantages for various industries. One of its key benefits is fire resistance, making it an ideal solution for sectors where safety is paramount, like electronics and furniture manufacturing. The expanded polypropylene (EPP) material provides excellent insulation, protecting sensitive items from heat damage during transit.

Additionally, EPP foam is highly versatile, allowing manufacturers to create tailored packaging solutions for unique products. Its low density makes it easy to handle and reduces transportation costs. Moreover, EPP molded foam is environmentally friendly; it’s recyclable and biodegradable, contributing to a greener supply chain. This sustainable aspect resonates with businesses aiming to reduce their ecological footprint.

Applications: Where Holland, Ohio's EPP Solutions Shine

In the realm of fire-resistant packaging solutions, Holland, Ohio’s EPP Solutions stand out for their innovative use of Expanded Polypropylene (EPP) foam. This lightweight molded foam packaging is a game-changer in various industries, offering exceptional protection while minimizing weight and material usage. The benefits are clear: reduced transportation costs, lighter products, and enhanced safety.

EPP solutions are particularly impactful in sectors like electronics, furniture, and construction. For instance, when delicate electronic components travel long distances, EPP foam provides a soft, yet robust, cushion that absorbs shocks and vibrations during transit. In the furniture industry, these inserts ensure that fragile items arrive at their destinations without a scratch, while in construction, they play a vital role in protecting valuable materials stored or transported on job sites.

Exploring Expanded Polypropylene Foam: Properties and Advantages

Expanded Polypropylene (EPP) foam is a lightweight, yet robust material that has gained significant popularity in various industries, especially for molded foam packaging in Holland, Ohio. Its unique properties make it an ideal choice for creating innovative and sustainable packaging solutions. EPP is known for its exceptional impact resistance, providing superior protection for fragile items during transportation. This characteristic makes it a game-changer for fragile product shipping, ensuring products arrive safely without sustaining damage.

One of the key advantages of EPP foam is its excellent thermal insulation properties. It effectively retains heat or cold, making it versatile for temperature-sensitive goods. Additionally, EPP’s low density and high compressive strength make it easy to mold into complex shapes while maintaining structural integrity. This versatility allows for customized packaging designs tailored to specific product needs, ensuring optimal protection and a professional finish. The benefits of EPP foam packaging contribute to a more efficient supply chain, reduced environmental impact, and enhanced customer satisfaction.