Industries rely on tailored industrial ventilation solutions—from exhaust ventilation for hazardous removal to supply ventilation systems for temperature regulation and air quality maintenance—to ensure worker safety, operational efficiency, and sustainability. Key factors include production processes, materials used, and employee numbers. Exhaust ventilation solutions are critical in removing toxic gases and dust, while supply ventilation systems introduce fresh air and control indoor climate. Centralized ventilation systems, integrating HVAC with industry-specific needs, offer enhanced air quality control, energy efficiency, and simplified maintenance for large industrial spaces. Recent advancements focus on intelligent, sustainable solutions, incorporating advanced filtration, smart sensors, and natural ventilation to optimize air quality, reduce noise, and minimize environmental impact.

In today’s industrial landscape, efficient HVAC (Heating, Ventilation, and Air Conditioning) integration is vital for optimal workplace environments. This comprehensive guide delves into the intricate world of industrial ventilation solutions, highlighting key aspects such as understanding specific needs, the role of exhaust ventilation solutions, and the importance of supply ventilation systems. We explore how integrating HVAC enhances efficiency, presents case studies of successful implementations, and looks ahead to future trends shaping the industry.

- Understanding Industrial Ventilation Needs

- The Role of Exhaust Ventilation Solutions

- Supply Ventilation Systems: Key Components

- Integrating HVAC for Optimal Efficiency

- Benefits of Centralized Ventilation Systems in Industries

- Case Studies: Successful HVAC Integration

- Future Trends in Industrial Ventilation

Understanding Industrial Ventilation Needs

In industries, understanding and optimizing ventilation is key to creating safe, productive, and sustainable working environments. Each industry has unique needs when it comes to industrial ventilation solutions, whether focusing on exhaust ventilation solutions for hazardous fumes or implementing supply ventilation systems to maintain optimal air quality and temperature control.

Effective industrial ventilation involves assessing factors like the type of production processes, materials used, and the number of employees present. For instance, manufacturing facilities require robust exhaust ventilation solutions to remove toxic gases and dust particles generated during operations. Conversely, data centers may prioritize supply ventilation systems to regulate temperature and ensure optimal performance of sensitive equipment.

The Role of Exhaust Ventilation Solutions

In industrial settings, proper ventilation is not just a recommendation; it’s a necessity for worker safety and operational efficiency. Exhaust ventilation solutions play a pivotal role in this regard by removing potentially hazardous gases, fumes, and dust from the workspace, ensuring a healthier and safer environment for employees. These systems are designed to capture and expel contaminant-laden air, preventing its circulation back into the work area. This is particularly crucial in industries where processes involve chemical reactions, metal fabrication, or any other activity that generates noxious substances.

Beyond safety, exhaust ventilation solutions contribute to the optimal performance of machinery and equipment. By maintaining clean and fresh air supply through supply ventilation systems, these solutions prevent the build-up of heat, dust, and debris, which can cause mechanical issues and reduce equipment lifespan. Efficient industrial ventilation solutions not only enhance worker comfort but also support energy efficiency goals by promoting natural airflow, reducing the need for excessive artificial cooling or heating.

Supply Ventilation Systems: Key Components

Supply ventilation systems play a pivotal role in providing fresh air and maintaining optimal indoor environments within industrial settings. These systems are designed to deliver controlled amounts of outside air, ensuring worker comfort and safety while enhancing overall productivity. Key components include high-efficiency filters that trap pollutants, ventilators for air movement, and dampers that regulate the flow to specific zones. By integrating these systems with heating, ventilation, and air conditioning (HVAC) infrastructure, industries can achieve effective dust control, improve air quality, mitigate risks associated with hazardous fumes, and create a healthier work environment.

Industrial ventilation solutions go beyond basic supply ventilation systems by incorporating advanced technologies such as energy-efficient motors, smart sensors for real-time monitoring, and variable speed drives to optimize performance. Exhaust ventilation solutions complement these efforts by removing contaminated air, further contributing to improved indoor air quality. The seamless integration of these components not only enhances the efficiency of HVAC systems but also reduces operational costs, making them essential elements in modern industrial facilities.

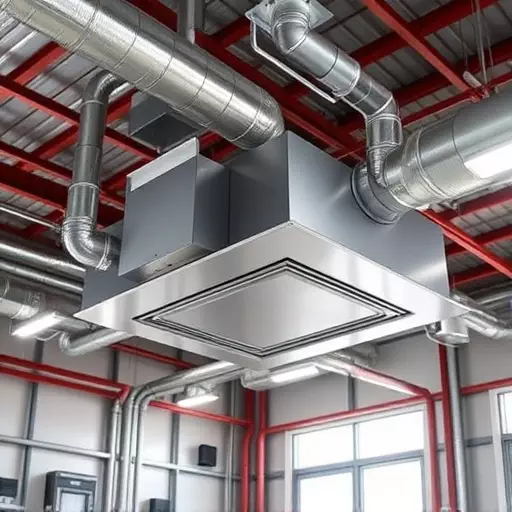

Integrating HVAC for Optimal Efficiency

In the quest for optimal efficiency in industrial settings, HVAC (Heating, Ventilation, and Air Conditioning) integration stands out as a game-changer. By seamlessly integrating HVAC systems with specific industrial needs, such as robust industrial ventilation solutions or tailored exhaust ventilation solutions, facilities can achieve significant energy savings and enhanced productivity. This involves designing supply ventilation systems that not only maintain ideal temperatures but also ensure high-quality air circulation, removing harmful contaminants while introducing fresh air.

Such integration offers a multitude of benefits, including improved indoor air quality, reduced operational costs, and increased worker comfort. Advanced HVAC technologies enable precise control over temperature, humidity, and airflow, catering to the unique demands of various industries. This customization ensures that processes are optimized, equipment performs at peak levels, and employees enjoy a healthier work environment, ultimately contributing to overall operational efficiency and sustainability.

Benefits of Centralized Ventilation Systems in Industries

In industries, efficient industrial ventilation solutions are paramount for maintaining optimal working conditions and ensuring worker safety. Centralized ventilation systems offer a multitude of benefits, especially when compared to disparate, localized exhaust ventilation solutions. By integrating a centralized system, industries can achieve better air quality control, allowing them to manage both the supply and exhaust of air more effectively. This ensures a steady flow of fresh air, reducing the buildup of harmful fumes, dust, or other pollutants that are common in many industrial settings.

Furthermore, these systems enhance energy efficiency through better temperature regulation. They can distribute conditioned air evenly throughout the workspace, minimizing energy wastage. This is particularly advantageous for large industrial spaces where maintaining consistent temperatures and air quality can be challenging with traditional, localized ventilation methods. Centralized systems also simplify maintenance and offer easier access for upgrades or modifications, making them a cost-effective supply ventilation system choice in the long run.

Case Studies: Successful HVAC Integration

In recent years, many industries have successfully integrated HVAC (Heating, Ventilation, and Air Conditioning) systems to optimize their operations. These case studies demonstrate the transformative power of efficient ventilation solutions, which go beyond basic comfort levels. For instance, in manufacturing hubs, implementing industrial ventilation solutions has significantly improved air quality by removing hazardous fumes and dust particles. This not only enhances worker safety but also extends equipment lifespan, leading to substantial cost savings.

Moreover, supply ventilation systems have been pivotal in maintaining optimal conditions for sensitive operations like pharmaceuticals and food processing. By controlling temperature, humidity, and air circulation, these exhaust ventilation solutions ensure product consistency and quality. Case studies show that proper HVAC integration can reduce energy consumption by up to 30%, making it an environmentally friendly and economically viable choice for industries aiming to stay competitive in today’s market.

Future Trends in Industrial Ventilation

The future of industrial ventilation is looking more intelligent and sustainable than ever before. With advancements in technology, we’re seeing a shift towards integrated HVAC (heating, ventilation, and air conditioning) systems that offer not just comfort but also improved energy efficiency. Industrial ventilation solutions are evolving to meet the demands of modern production methods, focusing on optimized air quality, reduced noise levels, and minimal environmental impact.

Exhaust ventilation solutions are becoming more sophisticated, employing advanced filtration systems and smart sensors to capture and remove hazardous pollutants effectively. Simultaneously, supply ventilation systems are being designed with energy conservation in mind, utilizing natural ventilation where possible and implementing precise control mechanisms to maintain optimal air circulation without excessive energy consumption. These trends promise to revolutionize industrial environments, creating safer, healthier, and more productive spaces for workers while contributing to a greener planet.