In Oak Harbor, Ohio, micro etching has emerged as a leading precision art form, offering unparalleled detail and versatility. This process creates intricate patterns on metals, glass, and plastics through a meticulous mask-and-etchant method, enhancing durability and product performance. With applications in medical devices, semiconductors, artistry, and décor, Oak Harbor is recognized as a hub for innovative micro etching solutions. Key benefits include complex geometry designs, material versatility, and exceptional accuracy compared to alternative methods like sandblasting, which focuses on larger-scale projects and textured finishes. Understanding these distinctions helps professionals select the optimal technique based on project requirements, ensuring superior outcomes in various industries.

“In the realm of metal surface finishing, micro etching and sandblasting stand out as distinct techniques. Based in Oak Harbor, Ohio, this article delves into the precise art of micro etching, its step-by-step process, and unparalleled benefits in unlocking intricate detail. We’ll also explore sandblasting, an alternative method, and provide a comprehensive comparison between these two processes to help you choose the optimal technique for your project.”

- Understanding Micro Etching: A Precise Art in Oak Harbor, Ohio

- The Micro Etching Process: Step-by-Step Guide

- Benefits of Micro Etching: Unlocking Precision and Detail

- Sandblasting: An Alternative Technique for Metal Surface Finishing

- Comparing Micro Etching and Sandblasting: Key Differences

- Choosing the Right Method: Considerations for Your Project

Understanding Micro Etching: A Precise Art in Oak Harbor, Ohio

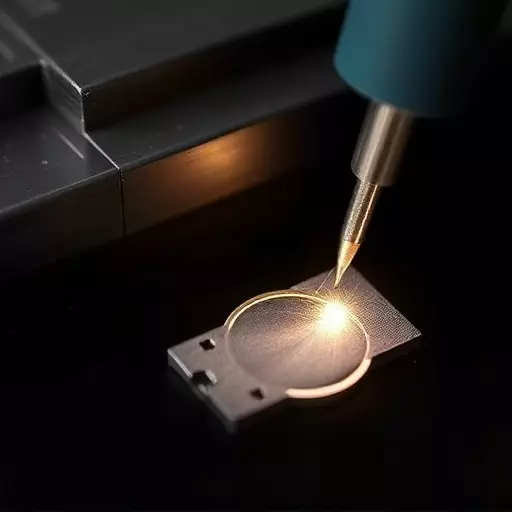

In the heart of Oak Harbor, Ohio, micro etching stands as a precise art form that has revolutionized various industries. This intricate process involves the controlled removal of material from a substrate using highly specialized tools and techniques. Each step is meticulously executed to achieve exceptional detail and accuracy, making it ideal for creating delicate designs on surfaces like metal, glass, or plastic.

The micro etching process in Oak Harbor Ohio offers numerous benefits, including enhanced surface finish, improved durability, and increased functionality. By removing only the desired amount of material, it allows for the creation of intricate patterns, texturing, and even microstructures that can significantly improve product performance. This advanced technique has found applications across diverse fields, from medical devices and semiconductor manufacturing to artistic sculptures and decorative items.

The Micro Etching Process: Step-by-Step Guide

The Micro Etching Process in Oak Harbor, Ohio begins with a detailed design that is translated into a mask. This mask acts as a template, protecting certain areas of the material while exposing others to an etchant. The etchant, typically a chemical solution, removes the exposed parts of the material at a microscopic level, leading to precise and intricate patterns.

Next, the material undergoes a series of steps: first, it’s placed in a chamber where the etchant is introduced; then, under controlled conditions, the etchant selectively eats away at the unprotected areas, following the contours of the mask. This process is repeated for different layers if a multi-level design is required. Once etching is complete, the mask is removed, revealing the final, finely etched pattern. The benefits of micro etching include unparalleled precision, versatility in material types, and the ability to create complex designs, making it a preferred method for various applications.

Benefits of Micro Etching: Unlocking Precision and Detail

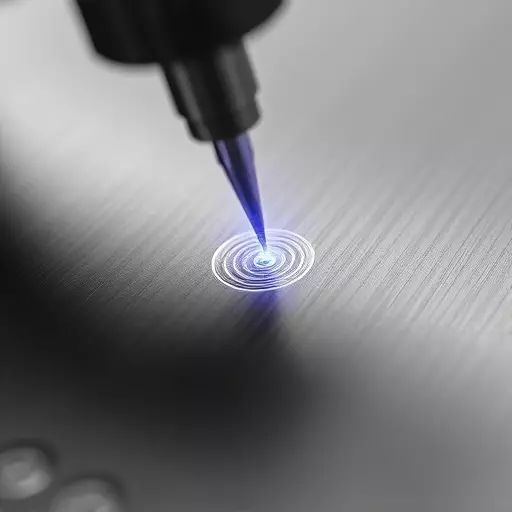

The micro etching process in Oak Harbor, Ohio, offers unparalleled precision and detail when it comes to carving and creating intricate patterns on various materials. Unlike sandblasting, which relies on abrasive media to etch surfaces, micro etching employs a more nuanced approach. This advanced technique allows for the manipulation of microscopic tools to incise or remove material, resulting in incredibly fine lines and details that would be challenging to achieve with coarser methods.

One of the key benefits of micro etching is its ability to produce complex geometries and intricate designs with exceptional accuracy. It finds applications in diverse fields, from manufacturing and electronics to medical devices and artistic sculptures. The level of detail achievable with micro etching opens doors for innovative product designs and enhances the functionality of many components, making it a preferred choice for professionals seeking top-tier precision in their projects.

Sandblasting: An Alternative Technique for Metal Surface Finishing

Sandblasting offers an alternative technique for metal surface finishing, providing a unique and precise way to shape and enhance materials. Unlike micro etching, which involves the careful removal of material through chemical or electrical processes in Oak Harbor, Ohio, sandblasting uses a high-pressure stream of abrasive media to etch and sculpt surfaces. This method is particularly effective for creating intricate patterns, texturing metal, and achieving specialized finishes.

The benefits of micro etching are well-documented, including superior precision and control over the final result. However, sandblasting presents its own advantages, such as the ability to work with larger areas and produce more dramatic effects quickly. It’s a versatile process suitable for various industries, from automotive to art, allowing for custom designs and specialized finishes that cater to diverse aesthetic preferences.

Comparing Micro Etching and Sandblasting: Key Differences

When comparing micro etching and sandblasting, two techniques used for precision surface modification, several key differences emerge. While both methods offer ways to create intricate patterns and textures, their approaches, applications, and inherent benefits vary significantly.

Micro etching involves using a high-precision tool to selectively remove material from a surface, resulting in detailed and delicate designs. This process is highly versatile, suitable for a wide range of materials, including metals, glass, and plastics. It’s particularly advantageous for creating complex microstructures and achieving fine line widths, making it ideal for industries like electronics, optics, and medical devices. On the other hand, sandblasting utilizes a stream of abrasive particles to etch or shape a surface. This method is generally more suitable for roughening surfaces, engraving larger patterns, or removing old coatings. While offering excellent versatility in terms of material types and surface profiles, sandblasting may not achieve the same level of precision and detail as micro etching. Benefits of micro etching include superior accuracy, control over feature size, and the ability to create intricate 3D structures. This process is often the preferred choice for applications requiring high-resolution patterns and smooth surface finishes.

Choosing the Right Method: Considerations for Your Project

When deciding between micro etching and sandblasting for your project in Oak Harbor, Ohio, it’s crucial to understand the unique benefits each method offers. Micro etching, a highly precise process, is ideal for intricate designs and detailed work. It allows for remarkable levels of accuracy, making it perfect for creating delicate patterns or structures on various materials. This method is particularly favored for its ability to achieve exceptional surface finishes, ensuring your project looks as good as it functions.

On the other hand, sandblasting offers a different set of advantages. It’s a versatile technique suitable for diverse projects, from shaping and engraving to deburring and cleaning. Sandblasting can handle more robust materials and complex geometries without compromising precision. This makes it a preferred choice when you need to etch or shape larger surfaces or when your project demands a unique texture or rougher finish.