In today's competitive market, CNC machining technology is transforming the packaging industry in Holland, Ohio. Custom, precise steel shipping racks offer enhanced product protection, optimized storage, reduced waste, and improved efficiency, withstanding harsh conditions. Benefits include increased productivity, better space utilization, and minimized damage during transit. Companies specializing in CNC machining for packaging provide high-performing, adaptable components, revolutionizing manufacturing processes and gaining a competitive edge.

The packaging industry is undergoing a transformation, driven by innovative technologies like CNC machining for packaging industry Holland Ohio. This article explores how custom CNC-machined packaging components are revolutionizing efficiency. We delve into the remarkable benefits of durable steel shipping racks, offering superior stability, versatility, and cost-effectiveness. By harnessing these advantages, businesses can enhance their storage and transportation processes, ensuring optimal product protection and streamlined operations.

- Revolutionizing Packaging Efficiency with Durable Steel Shipping Racks

- – Exploring the role of CNC machining in creating custom packaging components for enhanced productivity.

- Stability and Versatility: Key Advantages of Steel Shipping Racks

Revolutionizing Packaging Efficiency with Durable Steel Shipping Racks

In today’s fast-paced and highly competitive market, efficient packaging and shipping processes are paramount for businesses to stay ahead. Durable steel shipping racks, manufactured with precision CNC machining, are revolutionizing the packaging industry in Holland, Ohio, and beyond. These racks offer a multitude of benefits that streamline operations, enhance product protection, and reduce costs.

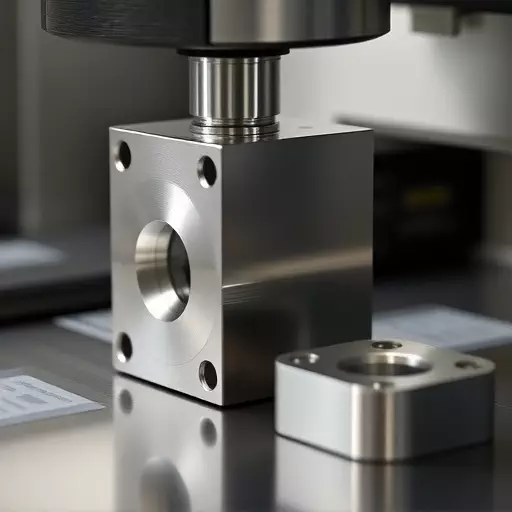

Custom CNC-machined packaging components ensure precise dimensions and intricate designs, allowing for optimized space utilization. This not only improves storage efficiency but also ensures products are securely held during transit, minimizing damage and loss. Moreover, the longevity of durable steel racks means they can withstand heavy loads and harsh environmental conditions, making them a reliable solution for even the most demanding packaging operations. The benefits of CNC machining in the packaging industry are clear: increased productivity, reduced waste, and improved overall efficiency.

– Exploring the role of CNC machining in creating custom packaging components for enhanced productivity.

In today’s competitive market, optimizing productivity and reducing costs are paramount for businesses in the packaging industry. CNC (Computer Numerical Control) machining has emerged as a game-changer, offering precise and customizable solutions to meet unique packaging needs. Located in Holland, Ohio, companies specializing in CNC machining for the packaging industry provide an array of custom CNC-machined packaging components tailored to enhance efficiency and improve product quality.

By leveraging advanced machinery and engineering expertise, these manufacturers enable businesses to create intricate designs with remarkable accuracy. Custom CNC-machined packaging components offer numerous benefits, including reduced lead times, increased consistency, and the ability to adapt quickly to changing product specifications. This technology revolutionizes traditional manufacturing processes, ensuring that packaging elements are not just functional but also optimized for performance, thereby fostering a competitive edge in the market.

Stability and Versatility: Key Advantages of Steel Shipping Racks

Durable steel shipping racks offer unparalleled stability and versatility, making them a staple in modern supply chain management. Their robust construction ensures they can withstand heavy loads and harsh conditions, providing a secure solution for storing and transporting goods efficiently. This stability is particularly beneficial for businesses in industries like CNC machining for packaging industry Holland Ohio, where precision and reliability are paramount. Custom CNC-machined packaging components demand robust support structures; steel racks excel in this area by maintaining their integrity even under significant stress.

The versatility of these racks is equally impressive. They can be easily configured to accommodate various package sizes and shapes, allowing businesses to maximize space utilization. This adaptability is a direct result of the precision engineering involved in their manufacturing, which often includes custom designs tailored to specific packaging needs. Benefits of CNC machining in packaging are evident here as it enables the creation of intricate rack systems that optimize workflow and reduce waste. From workshop floors to shipping docks, these racks provide a dynamic and reliable foundation for efficient packaging operations.