In Holland and Ohio, custom foam inserts for electronic devices have become a critical component in packaging due to their role in ensuring product safety and customer satisfaction. These regions, with their strategic locations near major shipping hubs and robust manufacturing capabilities, are at the forefront of producing specialized ESD-safe foam inserts tailored to protect electronics from electrostatic discharge. The use of anti-static foam materials is key in these custom solutions, which are precisely crafted using advanced CNC machining technology to fit a wide range of electronic products and mitigate the risks associated with ESD. This commitment to quality and innovation not only enhances product integrity upon arrival but also reduces return rates and builds customer confidence. The high standards set by Holland and Ohio in anti-static foam for electronics have established them as leaders in this specialized field, ensuring that electronic devices are safeguarded during transportation and storage, and maintaining the functionality of these items at the point of sale.

innovation in packaging technology has become a cornerstone of successful retail strategies. With the advent of precise CNC machining, protective foam inserts for electronics in Holland and Ohio are revolutionizing point-of-sale displays. This article delves into how custom foam inserts enhance product protection and presentation. We explore the critical role of ESD-safe and anti-static foam inserts in safeguarding sensitive electronics from both physical impact and electrostatic discharge. Discover the synergy between CNC precision and durable, bespoke foam solutions that provide unparalleled protection for electronic devices, ensuring they arrive at the point of sale in pristine condition.

- Optimizing Point-of-Sale Packaging with Custom Foam Inserts in Holland and Ohio

- Enhancing Electronics Protection: The Role of ESD-Safe and Anti-Static Foam Inserts in CNC Machining

- Precision and Durability: CNC Machining for Protective Foam Inserts for Electronics

Optimizing Point-of-Sale Packaging with Custom Foam Inserts in Holland and Ohio

In an era where consumer satisfaction and product protection are paramount, the strategic use of custom foam inserts plays a crucial role in ensuring that point-of-sale packaging meets the highest standards. Companies in Holland and Ohio have recognized the importance of this aspect, particularly in safeguarding electronics during transit. The regions’ proximity to major shipping hubs and their established manufacturing base make them ideal locations for businesses specializing in protective foam inserts for electronics. These custom solutions are tailored to fit a variety of products perfectly, providing not only physical protection but also meeting specialized requirements such as ESD-safe (Electrostatic Discharge) foam inserts. By incorporating anti-static foam materials, these inserts prevent damage from electrostatic discharge, which is a common concern for electronic components. This level of customization and care ensures that electronics arrive at their destination without suffering any damage during handling or shipping, thereby maintaining the integrity of the point-of-sale experience and preserving the product’s value and functionality.

The integration of anti-static foam inserts is particularly significant for electronic products that are sensitive to ESD. Holland and Ohio’s commitment to innovation in this domain has led to the development of advanced materials that provide optimal protection while being lightweight and cost-effective. These custom foam solutions not only shield against physical impacts but also from the subtle yet detrimental effects of static electricity. The result is a robust packaging strategy that upholds brand reputation, reduces return rates due to product damage, and enhances the overall customer experience. This attention to detail in point-of-sale packaging demonstrates a forward-thinking approach to manufacturing and distribution, setting companies in Holland and Ohio apart in their respective markets.

Enhancing Electronics Protection: The Role of ESD-Safe and Anti-Static Foam Inserts in CNC Machining

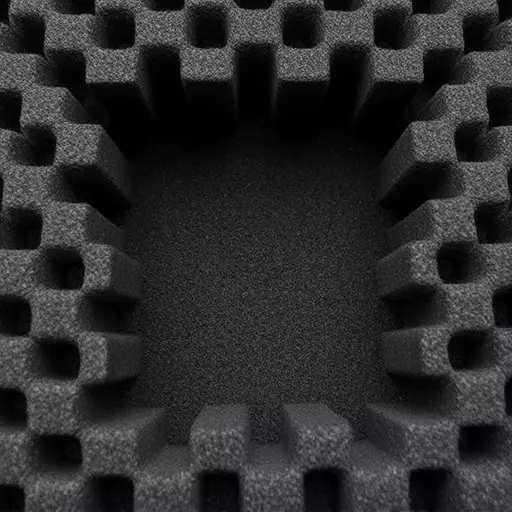

In the realm of electronics manufacturing and distribution, protecting sensitive components from electronic static discharge (ESD) is paramount to prevent damage and ensure product integrity. CNC machining plays a pivotal role in crafting protective foam inserts tailored for point-of-sale packaging, particularly in areas like Holland, Ohio, where precision and quality are synonymous with the region’s manufacturing ethos. These custom foam inserts are engineered not only to snugly fit various electronic devices but also to offer ESD protection. The incorporation of ESD-safe and anti-static foam materials within these inserts is a testament to the innovative solutions provided by local manufacturers. These materials are designed to dissipate static electricity, thereby safeguarding electronics from the potential damage caused by ESD events during handling and transportation.

The advantages of utilizing anti-static foam for electronics in CNC machining are manifold. The precision capability of CNC machinery allows for the creation of intricate foam insert designs that conform to the exact contours of electronic devices, providing superior shock absorption and preventing movement within the packaging. This ensures that even during rough handling or shipping, the delicate components remain undisturbed, reducing the risk of malfunction or permanent damage. Moreover, the use of anti-static materials in these inserts is a critical step in maintaining product quality and enhancing consumer trust. Companies in Holland, Ohio, specializing in custom foam inserts are at the forefront of this technology, offering solutions that are both effective and cost-efficient, thereby setting a standard for the industry in protecting electronics en route to the point-of-sale.

Precision and Durability: CNC Machining for Protective Foam Inserts for Electronics

In the realm of point-of-sale packaging, particularly for electronic items, protective foam inserts play a pivotal role in ensuring products arrive undamaged and intact. CNC machining has revolutionized the manufacturing of these custom foam inserts by delivering unparalleled precision and durability. Companies specializing in protective foam inserts for electronics in Holland, Ohio, leverage this advanced technology to create intricate patterns that perfectly fit the contours of various electronic devices. The Computer Numerical Control (CNC) process allows for a high degree of accuracy, ensuring each insert is tailored to the exact dimensions required to cushion delicate components without causing any harm. This precision is not just about fitting; it’s about creating a protective barrier that can withstand the rigors of transportation and handling.

The durability of CNC-machined foam inserts cannot be overstated. These custom solutions are designed to endure the stresses of storage and shipping, safeguarding the electronics they encase from impacts, drops, and vibrations that could otherwise lead to damage. For added assurance, these inserts can be engineered with ESD-safe foam properties, making them anti-static and thereby protecting sensitive electronic components from electrostatic discharge (ESD). This feature is particularly crucial for devices with integrated circuits and other ESD-susceptible elements. The result is a packaging solution that not only protects the product but also enhances the customer’s trust in the brand’s commitment to quality and care. Custom foam inserts, especially those with anti-static properties, are an indispensable component of point-of-sale packaging for electronics, ensuring that each device reaches its destination as if it were just packaged.