Effective industrial ventilation plays a pivotal role in maintaining hygiene and safety within food processing environments. This article delves into the critical aspects of implementing exhaust and supply ventilation solutions that optimize air quality and adhere to stringent safety standards in food production facilities. We explore design considerations essential for these systems, examine case studies highlighting their successful application, and provide insights into best practices for ensuring operational efficiency and compliance with industry regulations. Understanding the nuances of industrial ventilation solutions is key to safeguarding both workers and product integrity in the dynamic realm of food processing.

- Understanding the Role of Industrial Ventilation Solutions in Food Processing Environments

- Design Considerations for Effective Exhaust Ventilation Solutions in Food Production Facilities

- Implementation of Supply Ventilation Systems: Ensuring Air Quality and Safety Standards in Food Processing Plants

- Case Studies: Successful Application of Industrial Ventilation Solutions to Optimize Food Processing Operations

Understanding the Role of Industrial Ventilation Solutions in Food Processing Environments

Design Considerations for Effective Exhaust Ventilation Solutions in Food Production Facilities

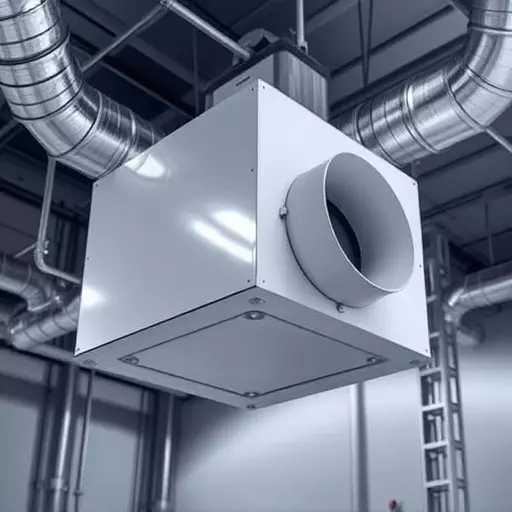

In the realm of food production facilities, maintaining a safe and hygienic environment is paramount. Design considerations for effective exhaust ventilation solutions are critical to manage airflow and control contaminants that arise from processing activities. Industrial ventilation solutions must be tailored to the specific operations within each facility, accounting for factors such as the type of food being processed, the volume of production, and the nature of the by-products generated. These exhaust systems play a vital role in removing heat, moisture, odors, and airborne particulate matter that can pose health risks to workers or spoil the product. The design must ensure proper air exchange rates to prevent the buildup of toxic substances or pathogens. Additionally, these systems should be integrated with supply ventilation systems to maintain a balanced environment, where fresh air is introduced at an optimal rate to complement the exhaust system’s performance. This balance is essential for creating a comfortable and productive work environment while safeguarding the integrity of the food products being manufactured.

To effectively address the needs of food processing facilities, exhaust ventilation solutions must adhere to stringent standards set by regulatory bodies. These systems are not merely about removing contaminants but also about managing energy efficiency and complying with health and safety regulations. The design should incorporate advanced filtration mechanisms to ensure that any recirculated air is clean and safe for reintroduction into the workspace. Moreover, the integration of automated controls allows for real-time monitoring and adjustment of the ventilation system’s performance in response to changing conditions on the production floor. This level of control and adaptability ensures that the food processing facility operates at peak efficiency while maintaining a clean and safe environment for all personnel involved.

Implementation of Supply Ventilation Systems: Ensuring Air Quality and Safety Standards in Food Processing Plants

Case Studies: Successful Application of Industrial Ventilation Solutions to Optimize Food Processing Operations

Within the food processing industry, the implementation of robust industrial ventilation solutions plays a pivotal role in maintaining a safe and efficient operational environment. One exemplary case study involves a leading meat processing plant that integrated advanced exhaust ventilation solutions to manage the high levels of pollutants generated during production. The system effectively removed contaminants, including volatile organic compounds (VOCs) and particulate matter, significantly reducing the risk of respiratory issues for workers and improving overall air quality. This upgrade not only enhanced worker safety but also increased the longevity of machinery by preventing the accumulation of dust and grime, thus optimizing production efficiency.

Another case in point is a large-scale bakery that utilized supply ventilation systems to maintain optimal humidity and temperature levels within its facilities. The precise control of these environmental factors prevented the proliferation of mold and bacteria, which could compromise product safety. Additionally, the consistent airflow provided by the supply system ensured uniform baking conditions, resulting in a more consistent product. This consistency has been crucial for maintaining the bakery’s reputation for high-quality goods, while also reducing waste and operational costs associated with substandard products. Both cases underscore the significance of tailored industrial ventilation solutions in achieving peak performance and safety standards within food processing operations.