The Arc Flash Study Process, adhering to NFPA 70E and IEC 61508, is a comprehensive methodology for electrical hazard analysis. It begins with a thorough review of facility infrastructure, equipment, and incident data, followed by computational analysis to simulate arc flash scenarios. This process identifies critical boundaries and required personal protective equipment (PPE), minimizing risks and ensuring worker safety in industrial settings. Regular analyses, equipment modifications, PPE upgrades, and employee training are best practices for ongoing arc flash safety management.

In today’s industrial landscape, arc flash protection is paramount for electrical safety. This comprehensive guide explores effective arc flash protection methods, encompassing the intricate arc flash study process, meticulous electrical hazard analysis, and adherence to vital arc flash safety standards. By understanding these key components, facilities can mitigate risks, ensure compliance, and foster a safer working environment. Discover best practices to navigate this critical aspect of electrical safety.

- Arc Flash Study Process: Unraveling the Methodology

- Electrical Hazard Analysis: Identifying and Mitigating Risks

- Arc Flash Safety Standards: Compliance and Best Practices

Arc Flash Study Process: Unraveling the Methodology

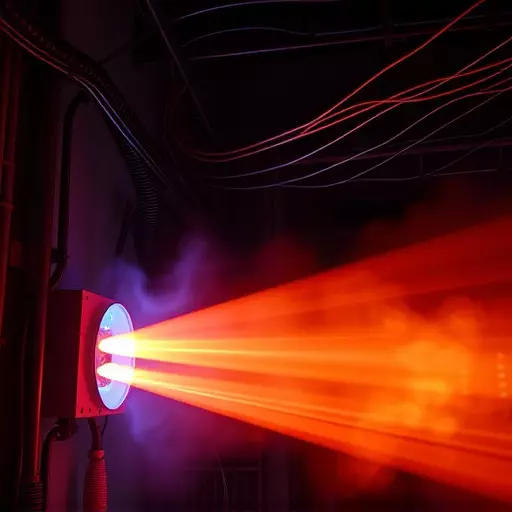

The Arc Flash Study Process is a comprehensive methodology designed to identify and mitigate electrical hazards in industrial settings. It involves a systematic analysis that begins with understanding the facility’s electrical infrastructure, equipment, and potential energy sources. This initial phase includes a detailed review of schematic diagrams, historical data on arc flash incidents, and an assessment of existing safety protocols. By gaining this knowledge, experts can pinpoint areas susceptible to arc flashes—an unexpected release of electrical energy resulting from ionization between conductors or within a conductor and ground.

Moving forward, the process entails performing a computational analysis to simulate various scenarios. This involves modeling different conditions, such as equipment failures, short circuits, or human errors, to predict potential arc flash events. The outcome provides critical data on arc flash boundaries—the safe distances from an arc source—and the personal protective equipment (PPE) required for workers in those areas. Adhering to recognized arc flash safety standards, like NFPA 70E, ensures that these studies are conducted rigorously and that appropriate measures are taken to protect personnel and prevent severe injuries or fatalities associated with electrical hazards.

Electrical Hazard Analysis: Identifying and Mitigating Risks

Electrical Hazard Analysis is a critical step in ensuring arc flash safety within industrial and commercial settings. It involves a comprehensive study process that identifies potential risks associated with electrical systems, equipment, and processes. By meticulously examining each aspect of an environment, from wiring configurations to operational procedures, professionals can pinpoint areas prone to arc flash events. These events, though often unforeseen, carry significant risks due to the intense light, heat, and force they generate.

During this analysis, experts consider various factors, such as voltage levels, current ratings, and proximity of personnel. They also evaluate existing safety protocols and equipment like protective clothing, shielding mechanisms, and interruption devices. The goal is not just to identify hazards but to mitigate them through strategic interventions that align with established arc flash safety standards. This proactive approach ensures a safer working environment for employees while minimising the potential for severe injuries or property damage caused by these powerful electrical phenomena.

Arc Flash Safety Standards: Compliance and Best Practices

Arc Flash Safety Standards: Compliance and Best Practices

Compliance with arc flash safety standards is paramount in any industrial setting where electrical hazards exist. A thorough understanding of these standards, such as NFPA 70E or IEC 61508, forms the foundation for a robust arc flash protection program. The arc flash study process involves a meticulous evaluation of existing electrical systems, identifying potential arc flash risks, and implementing appropriate controls. This includes equipment design modifications, personal protective equipment (PPE) upgrades, and safety procedures tailored to specific workplace conditions.

Best practices extend beyond compliance, emphasizing proactive risk mitigation strategies. Regular electrical hazard analyses should be conducted to ensure that changes in the facility or equipment do not introduce new risks. Additionally, continuous employee training on arc flash safety standards and proper PPE usage is essential. Engaging in these practices fosters a culture of safety, minimizing the potential for severe injuries or fatalities associated with arc flashes.