Steel packaging solutions are favored in the chemical industry for their strength and adaptability, safely transporting hazardous materials. The shift towards sustainability has driven demand for eco-friendly steel packaging, with its recyclability reducing environmental impact. Customized steel packaging allows manufacturers to create specialized containers tailored to specific product needs, enhancing protection and brand visibility. Advancements in manufacturing and digital transformation are paving the way for innovative, sustainable steel packaging solutions that meet growing environmental and functional requirements.

Steel packaging has emerged as a leading solution in the chemical industry, offering robust protection and sustainable benefits. This comprehensive guide explores the multifaceted world of steel packaging for chemicals, delving into its materials, environmental advantages, and tailored applications. From understanding the material’s strength to navigating safety standards and future trends, we uncover why custom steel packaging is revolutionizing chemical distribution, providing efficient, eco-friendly, and safe solutions across diverse sectors.

- Understanding Steel Packaging for Chemicals: Materials and Benefits

- The Rise of Sustainable Steel Packaging: An Eco-Friendly Approach

- Custom Steel Packaging: Tailoring Solutions to Specific Chemical Needs

- Safety and Compliance Considerations in Steel Chemical Packaging

- Applications of Steel Packaging in Various Chemical Industries

- Future Trends in Steel Packaging for Chemicals

Understanding Steel Packaging for Chemicals: Materials and Benefits

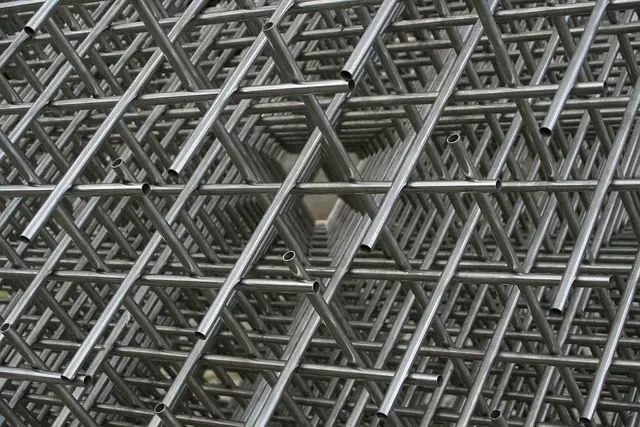

Steel packaging solutions have emerged as a preferred choice in the chemical industry due to their exceptional strength and versatility. These packages are designed to withstand harsh handling conditions, ensuring the safety and integrity of hazardous or corrosive substances during transportation and storage. The materials used in steel packaging are robust and durable, providing superior protection against leaks and contamination. With advancements in manufacturing techniques, sustainable steel packaging has become a viable option, offering environmental benefits without compromising on quality.

Custom steel packaging plays a crucial role in catering to the unique requirements of various chemical products. Manufacturers can create specialized designs, incorporating specific dimensions, shapes, and features as per client needs. This level of customization not only enhances product protection but also allows for efficient inventory management and improved brand visibility. Sustainable practices in steel packaging production further contribute to reducing environmental impact, making it an attractive choice for eco-conscious businesses.

The Rise of Sustainable Steel Packaging: An Eco-Friendly Approach

The shift towards sustainability has prompted a significant rise in the demand for eco-friendly steel packaging solutions. Traditional packaging materials often contribute to environmental degradation, making sustainable alternatives increasingly necessary. Sustainable steel packaging offers a promising solution by combining strength and durability with a reduced environmental footprint. This type of packaging is designed to minimize waste, maximize recycling potential, and decrease the overall carbon footprint associated with chemical transportation and storage.

Customized steel packaging plays a crucial role in this transition. Manufacturers can now create specialized containers tailored to specific chemical products’ unique requirements. These custom designs not only enhance product protection but also enable efficient use of materials, reducing waste further. The growing preference for sustainable alternatives has catalyzed innovation in the steel packaging industry, leading to more advanced and environmentally conscious steel packaging solutions.

Custom Steel Packaging: Tailoring Solutions to Specific Chemical Needs

Safety and Compliance Considerations in Steel Chemical Packaging

When it comes to storing and transporting chemicals, safety is paramount. Steel chemical packaging offers a robust solution that meets stringent industry regulations, ensuring the protection of both products and the environment. This is particularly important in sectors where hazardous substances are involved, as steel’s superior strength and resistance to corrosion provide a reliable barrier against leaks or damage.

Sustainable steel packaging has emerged as a preferred choice for many businesses seeking eco-friendly alternatives without compromising on quality. Custom steel packaging allows manufacturers to design specific solutions tailored to unique chemical formulations and application requirements. This versatility, coupled with the industry’s adherence to strict compliance standards, makes steel an attractive option for businesses looking to meet both safety needs and environmental sustainability goals.

Applications of Steel Packaging in Various Chemical Industries

Steel packaging solutions have become a game-changer across various chemical industries, offering unparalleled strength and versatility. From aggressive chemicals to delicate substances, steel packaging is widely used due to its ability to withstand extreme conditions, including high temperatures, corrosion, and pressure. Its durability ensures the safe transportation and storage of hazardous materials, making it an indispensable choice for many sectors.

The demand for sustainable steel packaging has been rising, driven by environmental considerations and regulatory changes. Steel is a fully recyclable material, which reduces waste and carbon footprint compared to many other packaging options. Moreover, custom steel packaging allows manufacturers to design specific containers tailored to unique product requirements, enhancing safety, efficiency, and brand identity. This versatility makes steel an attractive option for chemical companies seeking both functionality and sustainability in their packaging solutions.

Future Trends in Steel Packaging for Chemicals

The future of steel packaging for chemicals is poised for significant growth, driven by an increasing demand for sustainable and durable solutions. As environmental concerns continue to rise, manufacturers are seeking eco-friendly alternatives to traditional packaging materials. Steel packaging solutions offer a promising path forward due to their inherent recyclability and longevity, making them a preferred choice for the chemical industry. The market is witnessing a shift towards custom steel packaging designs that cater to specific product requirements, ensuring optimal protection and efficiency in distribution.

Innovations in sustainable steel packaging are expected to gain momentum, with advancements in manufacturing processes aiming to reduce waste and carbon footprint. This includes exploring new alloys and coating technologies that enhance barrier properties and improve product shelf life. With a focus on minimizing environmental impact, the industry is likely to embrace digital transformation, enabling precise customization and efficient production runs for niche chemical products.